En el hipercompetitivo mercado inmobiliario de Dubai, El lanzamiento de un proyecto requiere más que una simple presentación.; exige un espectáculo. Este estudio de caso ofrece una mirada entre bastidores a la creación del 'Sky Oasis'.’ modelo de torre, un proyecto emblemático definido por la complejidad arquitectónica, una línea de tiempo implacable, y el objetivo estratégico de impulsar ventas masivas sobre plano en la mundialmente reconocida exposición Cityscape Global.. Descubra el proceso paso a paso de cómo una fusión de tecnología avanzada y maestría artesanal transformó un desafío enorme en una historia de éxito sin precedentes.. Esta es la anatomía de un modelo de héroe..

Tabla de contenido

La anatomía de un desafío histórico

Todo gran resultado comienza con un desafío formidable. El 'Oasis del Cielo'’ El proyecto se definió por cuatro presiones clave que debían gestionarse con absoluta precisión.. El fracaso en cualquiera de estas áreas habría puesto en peligro toda la campaña de lanzamiento multimillonaria.. Para entender cómo abordamos esto, Es útil comenzar con los principios fundamentales de la creación de modelos., que cubrimos en nuestro Guía definitiva para modelos arquitectónicos de alta gama.

1. La visión arquitectónica: Una fachada paramétrica compleja

La característica distintiva de la Sky Oasis Tower fue su impresionante fachada.. Diseñado por un estudio de arquitectura de renombre mundial., fue un fluir, paramétrico, estructura similar a una pantalla que envolvía la torre, inspirado en las arenas movedizas del desierto. Este no era un simple patrón repetitivo que pudiera replicarse fácilmente.. fue un complejo, orgánico, y diseño no uniforme con intrincados, curvas fluidas. Desde el punto de vista de la fabricación, esto presentó un desafío inmediato: Sería físicamente imposible crear este diseño con precisión utilizando la tecnología tradicional., técnicas manuales de modelismo. Exigía una solución de alta tecnología..

2. La línea de tiempo implacable: 12 Semanas para el show

El plazo era absoluto e inamovible.: 12 semanas. Este fue el tiempo total desde el momento en que se firmó el contrato hasta el momento en que el modelo tuvo que estar completamente ensamblado., iluminado, y operativo en el piso de exhibición de Cityscape Global en Dubai. Este cronograma agresivo tuvo que tener en cuenta:

- Consulta y refinamiento del diseño inicial..

- Modelado digital meticuloso y aprobación del cliente..

- Fabricación en varias etapas de cientos de componentes únicos.

- Pintura compleja, refinamiento, e integración electrónica.

- Un complejo proceso de envío internacional y despacho de aduanas.

No había absolutamente ningún búfer para errores o retrasos.. Cumplir este cronograma requirió un flujo de trabajo impecable, un tema que exploramos en nuestra guía para Gestión de proyectos modelo en el extranjero.

3. El desafío logístico: Un envío de alto valor de 10.000 kilómetros

El modelo terminado era de gran valor., frágil, y absolutamente irremplazable activo que tuvo que viajar a través 10,000 kilómetros desde nuestro taller en China hasta Dubai, EAU. Los riesgos logísticos eran importantes.. Se enfrentó al potencial de sufrir daños catastróficos durante el tránsito., Las notorias complejidades del despacho de aduanas en los Emiratos Árabes Unidos., y la necesidad de ser perfecto, Montaje rápido in situ por parte de un equipo local que nunca antes había visto el modelo.. La ciencia de esto es algo que detallamos en nuestro Guía para el envío seguro de modelos internacionales.

4. El objetivo estratégico: Impulsar las ventas sobre plano

Este modelo no era una obra de arte.. Era un motor de ventas de alto rendimiento.. Su principal retorno de la inversión (ROI) se mediría en contratos firmados en el recinto ferial. Tenía que ser una herramienta poderosa y persuasiva que pudiera convencer a inversores sofisticados y compradores de viviendas exigentes para que comprometieran un capital significativo en un proyecto que aún no existía.. Su éxito estaría determinado por su capacidad para crear deseo y generar una confianza inquebrantable.. Su poder para hacer esto es un tema central en nuestro artículo., Cómo un modelo inmobiliario de primer nivel puede duplicar sus ventas.

| El 'Oasis del Cielo'’ Matriz de desafíos del proyecto | ||

|---|---|---|

| Área de desafío | Obstáculo específico | Factor clave de éxito |

| Arquitectónico | Complejo, fachada paramétrica no uniforme. | Fabricación digital avanzada (3D impresión). |

| Línea de tiempo | 12 semanas de principio a fin, incluyendo envío internacional. | Un altamente eficiente, flujo de trabajo de producción paralelo. |

| Logistica | Transporte seguro de un objeto frágil, Activos de alto valor y despacho de aduanas fluido.. | Experto, embalaje diseñado y documentación meticulosa. |

| Comercial | Necesario para impulsar importantes ventas sobre plano en una exposición importante. | A “Guau” factor creado por detalles excepcionales e iluminación interactiva. |

El “Cero obstáculos” Proceso en acción: Un desglose semana a semana

Enfrentar este formidable desafío requirió una impecable, plan de ejecución de varias fases. Esta es una mirada detrás de escena de cómo se desarrolló el proyecto..

Fase 1 (Semanas 1-2): Estrategia, Consulta, y Fundación Digital

El proyecto no empezó en el taller., pero en una sala de conferencias virtual. Nuestra videollamada inicial conectó al equipo de arquitectura del cliente en Londres con nuestro gerente de proyecto dedicado y director técnico principal.. Esto no fue solo una introducción; Fue una sesión de profunda alineación estratégica.. Discutimos los desafíos centrales., especialmente el mejor enfoque para fabricar la fachada paramétrica manteniendo la intención de diseño del arquitecto. Establecimos en colaboración un protocolo de comunicación firme (acordamos informes de progreso semanales por correo electrónico) y establecimos las fechas clave para los comentarios y la aprobación de los clientes.. Este paso inicial es vital, un proceso que cubrimos en nuestra guía, 10 Preguntas críticas para hacer antes de contratar a un fabricante de modelos.

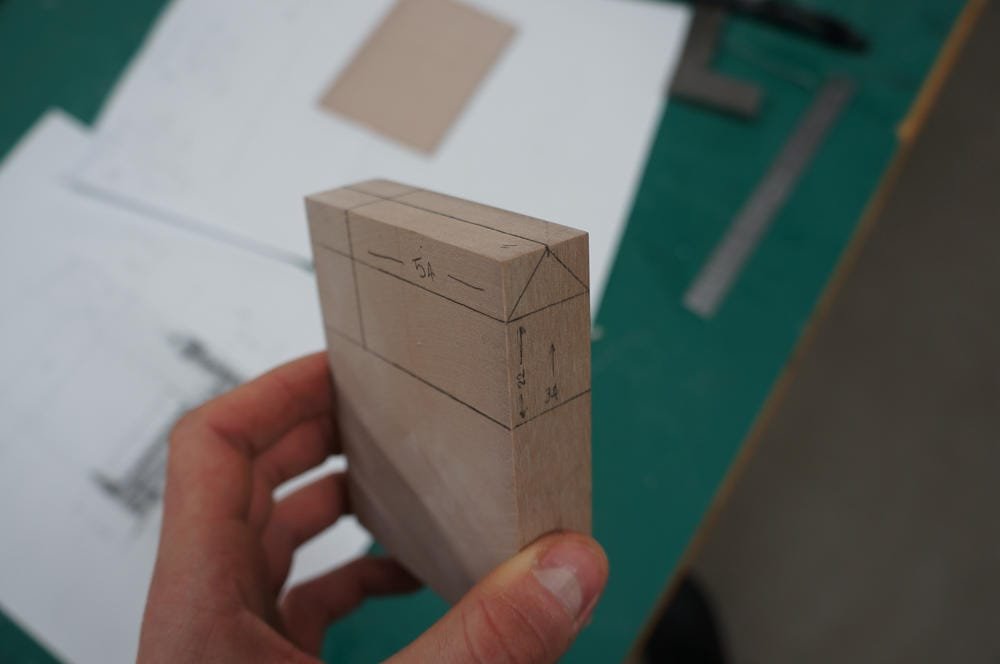

Inmediatamente después de la llamada, Nuestro equipo técnico tomó los complejos archivos Rhino y Grasshopper del arquitecto y comenzó el meticuloso proceso de convertirlos en un archivo maestro 3D listo para fabricar.. Esto implicó racionalizar la compleja geometría., Planificación de las divisiones seccionales óptimas para el envío y el montaje., y diseño del núcleo estructural interno..

Fase 2 (Semanas 2-3): Revisión digital y aprobación del cliente

Este fue el hito más importante de todo el proyecto.. Antes de cortar o imprimir cualquier material físico, Enviamos el modelo digital 3D completo al equipo del cliente para su revisión formal y aprobación.. Este “gemelo digital” fue perfecto, 1-réplica virtual to-1 del modelo final. Incluía cada detalle, desde los paneles individuales de la fachada hasta la distribución propuesta de la iluminación interior y exterior.

Durante su revisión, El equipo del cliente solicitó una pequeña modificación en la marquesina de entrada al podio.. Porque todavía estábamos en el flexible, fase digital, Nuestro equipo pudo realizar este cambio en cuestión de horas., sin impacto en el costo o el cronograma. Si se hubiera solicitado este cambio después de que hubiera comenzado la fabricación física, habría causado un retraso importante y habría añadido miles de dólares al coste. Esta etapa de prueba digital es la herramienta definitiva para mitigar riesgos..

Fase 3 (Semanas 3-9): La estrategia de fabricación híbrida

Con la prueba digital firmada formalmente, el taller cobró vida. Para satisfacer las demandas de velocidad y calidad., empleamos una sinergia “híbrido” estrategia de fabricación, donde se utilizaron diferentes tecnologías para diferentes tareas en función de sus fortalezas únicas.

| El flujo de trabajo de fabricación híbrida | ||

|---|---|---|

| Componente | Tecnología utilizada | Razón |

| Base topográfica | 5-Fresado CNC de eje | Tallado en espuma de alta densidad, Este método proporcionó una precisión de contorno perfecta para el entorno costero de Dubai y una robusta, base estable. |

| Núcleo de la torre & Placas de piso | Corte con láser | El núcleo estructural interno y todo 70 Las placas de piso individuales fueron cortadas con láser con precisión a partir de láminas acrílicas., garantizando una perfecta alineación y estabilidad de la estructura alta. |

| Fachada Paramétrica | Impresión 3D SLA | el complejo, La fachada orgánica fue asaltada. 200 único, paneles entrelazados. Cada uno fue fabricado utilizando nuestras impresoras 3D SLA de gran formato para un resultado impecable., Acabado superficial liso como molde de inyección. |

Esta asignación inteligente de tecnología es un principio fundamental que exploramos en nuestro artículo sobre Artesanía moderna vs. Trabajo manual tradicional.

Fase 4 (Semanas 9-11): El arte del acabado, Asamblea, e integración

Con todos los componentes fabricados., el enfoque se centró en el alto toque, Habilidades artesanales que dan vida a un modelo..

El acabado impecable: Pintura de grado automotriz

cada uno de los 200 Los paneles de fachada únicos fueron meticulosamente lijados a mano para eliminar cualquier línea de capa microscópica del proceso de impresión.. Luego fueron llevados a nuestro dedicado, cabina de pintura sin polvo. una costumbre, Se aplicó pintura metálica multicapa con un sutil acabado nacarado para que coincidiera perfectamente con las especificaciones del arquitecto., creando un impresionante, efecto brillante que cambiaría con la luz. Este nivel de acabado es crítico., un tema que detallamos en nuestro Guía de materiales y acabados modelo.

Creando un mundo creíble: Paisajismo hiperrealista

Nuestro dedicado equipo de paisajismo se centró en crear un ambiente auténtico y lujoso en Dubai.. No se trataba de colocar esponjas verdes genéricas. Se trataba de hacer a mano 300 Palmeras individuales a escala de diferentes alturas., creando realista, Efectos de agua de varias capas para el puerto deportivo., y agregando finos detalles como autos de lujo, yates, y personas escaladas con precisión para darle vida a la escena. Revelamos las técnicas detrás de esta forma de arte en Los secretos del paisajismo de modelo realista.

El “Guau” Factor: Un sistema de iluminación controlado por aplicación de nivel 3

Esta fue la característica de ventas crítica del modelo.. Nuestro equipo electrónico interno diseñó, construido, e instalé un totalmente programable, sistema de iluminación controlado por aplicación.

- Detalles técnicos: Instalamos sobre 1,500 blanco cálido direccionable individualmente (3000k) micro-LED. Todo el sistema estaba controlado por una aplicación de iPad diseñada a medida que se comunicaba de forma inalámbrica con el modelo..

- Características clave: La aplicación incluía una hermosa “Día/Noche” simulación, un “Tour de comodidades” secuencia que destacó características clave, y la herramienta de ventas definitiva: a “Buscador de unidades” que permitió al equipo de ventas tocar un número de apartamento específico en el iPad, que luego iluminaría ese single, unidad individual en el modelo físico.

Este nivel de interactividad transforma un modelo de una pantalla estática a una herramienta de ventas dinámica.. Explora las posibilidades en El uso estratégico de la iluminación en modelos arquitectónicos.

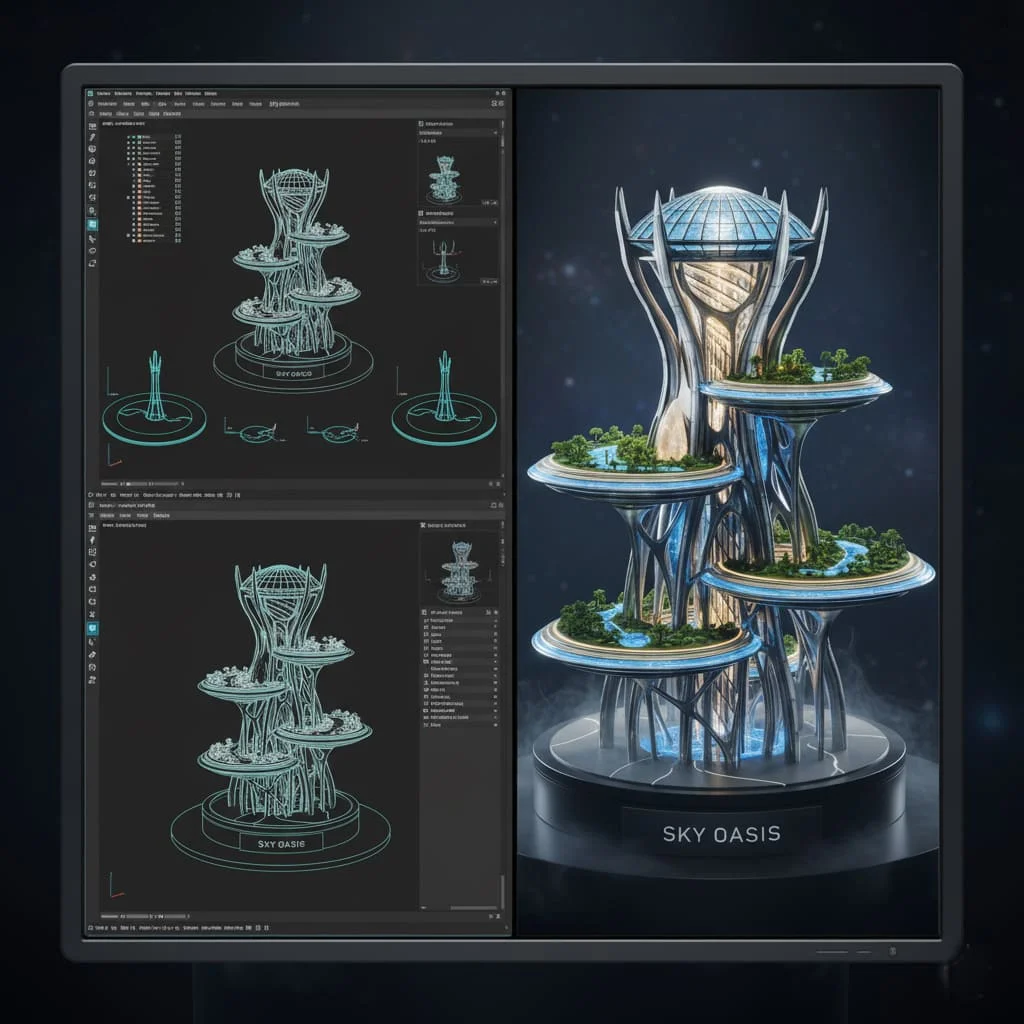

Fase 5 (Semana 12): La ciencia de la logística y el montaje in situ

Con solo unos días de sobra, el modelo estaba listo para su viaje. Para garantizar una llegada impecable, ejecutamos nuestro protocolo logístico probado.

- El “A prueba de balas” Caja: el modelo, ya diseñado en tres secciones principales entrelazadas, fue cuidadosamente desmontado. Cada sección fue asegurada en su propio diseño personalizado., forrado de espuma, Flightcase reforzado con acero.

- Documentación impecable: Nuestro dedicado equipo de logística preparó una factura de aduana detallada, certificado de origen, y todos los demás trámites necesarios para los EAU, asegurando un suave, entrada sin demoras al país. El envío se realizó mediante transporte aéreo totalmente asegurado..

- Asamblea en el sitio: Proporcionamos al equipo de eventos local del cliente una información detallada, Vídeo paso a paso y folleto de instrucciones plastificado.. El diseño modular fue tan intuitivo que su equipo pudo desembalar y ensamblar perfectamente las tres secciones en menos de una hora..

La revelación: Generando un impacto en el escenario mundial

La verdadera prueba del modelo no fue en nuestro taller., pero bajo las brillantes luces de la exposición inmobiliaria más competitiva del mundo. El resultado fue un éxito rotundo. A llegado, El equipo del cliente desempacó el modelo y lo encontró en perfectas condiciones.. El sencillo proceso de montaje significó que lo tuvieron configurado y completamente operativo en minutos., no horas, aliviar el inmenso estrés previo al espectáculo.

“El modelo no era solo una parte de nuestro stand.; él era nuestro stand. La gente estaba hipnotizada. La cola para ver la demostración de iluminación era constante. Le dio a nuestro equipo de ventas la plataforma definitiva para contar la historia del proyecto.” – Director de Desarrollo, Proyecto Oasis del Cielo

Desde el momento en que se abrieron las puertas de Cityscape Global, El stand de Sky Oasis estuvo dominado por el resplandor, modelo interactivo. Inmediatamente se convirtió en el punto focal de toda la sala de exposiciones., un faro que atrajo a posibles compradores, medios internacionales, e incluso impresionó a los competidores. lo táctil, La naturaleza tridimensional del modelo llamó la atención de una manera que las pantallas planas de los stands vecinos simplemente no podían igualar..

Los resultados: De 'Guau’ Factor de retorno de la inversión tangible

Si bien el impacto visual y el revuelo mediático fueron innegables, el 'Oasis del Cielo'’ El modelo fue encargado para un propósito comercial principal.: para impulsar las ventas. Los resultados de la exposición de tres días fueron extraordinarios y demostraron un claro y poderoso retorno de la inversión..

| 'Oasis del cielo’ Modelo de retorno de la inversión (ROI) Análisis | ||

|---|---|---|

| Métrico | Resultado | Impacto en el proyecto |

| Unidades sobre plano vendidas | Encima 100 reservas aseguradas durante el evento de 3 días. | Representado sobre 30% del total de unidades residenciales de la torre, creando un enorme impulso de ventas desde el primer día. |

| Grandes acuerdos de inversión | Dos acuerdos de compra al por mayor obtenidos de fondos de inversión internacionales. | La claridad y la profesionalidad del modelo se citaron como factores clave para generar confianza en los inversores.. |

| Menciones en los medios | Destacado en las principales publicaciones regionales como Gulf News y Arabian Business. | Generó millones de dólares en valor publicitario equivalente y estableció el proyecto como un hito.. |

| Aceleración del ciclo de ventas | El tiempo promedio para cerrar un trato se redujo significativamente. | El modelo respondió visualmente a las preguntas y construyó una conexión emocional rápidamente., empoderando al equipo de ventas. |

Conclusiones clave para su próximo proyecto emblemático

El 'Oasis del Cielo'’ El proyecto ofrece varias lecciones poderosas para cualquier desarrollador o arquitecto que encargue un modelo arquitectónico de alto riesgo..

- Lección 1: Invierta en un informe detallado. El éxito del modelo comenzó con una clara, comprensión compartida de su propósito estratégico: impulsar las ventas. Este objetivo informó cada decisión posterior..

- Lección 2: Confíe en el proceso híbrido. La fusión de la impresión 3D para la compleja fachada y el meticuloso acabado a mano para los toques finales fue la clave para lograr una precisión perfecta y un arte impresionante..

- Lección 3: No escatime en iluminación interactiva. El sistema de iluminación controlado por una aplicación no fue un truco; Era la función de ventas interactiva más poderosa y efectiva del modelo..

- Lección 4: Un gran proceso elimina riesgos a distancia. Con un robusto, proceso transparente, un gerente de proyecto dedicado, y comunicación clara, gestionar todo el proyecto desde otro continente no fue un obstáculo, sino una experiencia fluida y eficiente.

Conclusión: Más allá de un modelo: un activo estratégico

La historia del 'Sky Oasis' de Dubái’ El modelo de torre es un testimonio del poder de una visión bien ejecutada. Una arquitectura formidable, logístico, y el desafío comercial se enfrentó con una solución de clase mundial, proceso de fabricación híbrido. El resultado fue un impresionante modelo arquitectónico que hacía más que representar un edificio.; cautivó a una audiencia internacional, Empoderó a un equipo de ventas., y entregado tangible, resultados empresariales sin precedentes.

Este estudio de caso demuestra que un gran modelo es una inversión., no es un gasto. Es un activo estratégico que trabaja incansablemente para generar confianza., crear deseo, y convertir un proyecto visionario en un rotundo éxito comercial.

Listo para crear su propio punto de referencia?

Si está listo para discutir cómo un modelo histórico puede impulsar el éxito de su próximo proyecto, nuestro equipo internacional está aquí para ayudar. Contáctanos gratis, consulta sin compromiso.