Table of Contents

The Strategic Imperative: Why Go Global in the First Place?

Before we dive into the “how,” it’s crucial to understand the compelling “why.” The decision to work with a specialized overseas partner is not about compromise; it’s about gaining a competitive edge that is often unavailable locally. Leading firms are embracing a globalized production model to tap into a unique combination of benefits that directly impact their project’s success.

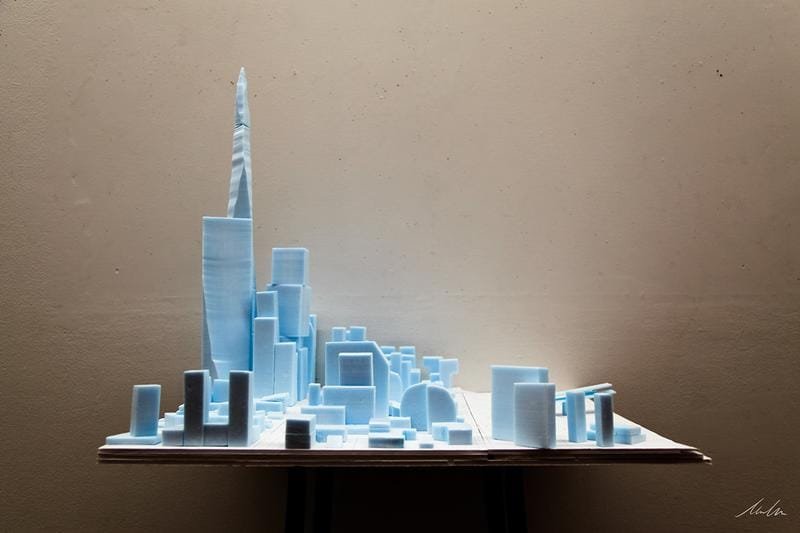

Accessing an Unparalleled Ecosystem of Skill and Technology

Specialized manufacturing hubs, particularly in China, offer an industrial ecosystem that is difficult to replicate elsewhere. This means access to large, highly skilled teams of artisans who have dedicated their careers to the craft of model making. These teams are supported by massive in-house investments in state-of-the-art technology, including entire fleets of industrial-grade 3D printers, multi-axis CNC mills, and high-powered laser cutters. The fusion of master artisanship and cutting-edge tech, a topic we explore in Modern Craft vs. Traditional Handwork, results in a final product of exceptional quality.

Achieving a Superior Value Proposition

The most significant advantage is the powerful value proposition. This is not simply about being “cheaper.” It’s about achieving a level of quality, detail, scale, and technological sophistication that would be prohibitively expensive in most Western markets. For the same budget, a client can often commission a model with more features, a higher level of finish, and greater overall impact. It’s an opportunity to maximize the return on your investment, creating a powerful asset that can help you double your property sales. These benefits are part of a larger economic and industrial reality, which we explore in full detail in our in-depth analysis, The China Advantage: Why Global Firms Source Architectural Models Here.

The “Zero Obstacles” Framework: A Phase-by-Phase Guide to Flawless Execution

A successful overseas project is not a matter of luck; it’s a matter of process. This phase-by-phase framework demystifies the remote workflow, showing how a structured, transparent process eliminates the traditional obstacles of distance.

Phase 1: Pre-Project Due Diligence – Setting the Foundation for Success

This is the most important step. An astonishing 90% of potential problems are eliminated right here, before any contracts are signed or money changes hands. Choosing a partner with a proven, transparent, and client-centric process is the single greatest mitigator of risk. To understand this crucial first step, we highly recommend reading our foundational pillar page: The Ultimate Guide to High-End Architectural Models.

Technical Vetting: Beyond the Portfolio

A beautiful portfolio is a starting point, not a conclusion. You must look past the “hero shots” to verify their true technical capabilities. This means confirming the specifics of their in-house technology. Ask for a list of their machines—how many 3D printers do they operate? What are their build volumes? What laser-cutting technology do they use? This tells you if they have the industrial-scale capacity to handle your project without outsourcing, which adds risk and cost. The role of this technology is a revolution we cover in our Guide to 3D Printing Models.

Process Vetting: Auditing Their Workflow

This is where you audit their workflow. A world-class partner will be able to confidently and clearly explain their end-to-end process. They should have ready answers for how they handle communication, project milestones, quality control, and international logistics. If their answers are vague or disorganized, so is their process. We have created the definitive checklist for this crucial stage. You must read 10 Critical Questions to Ask Before Hiring a Model Maker before you commit to any partner.

Phase 2: The Kick-Off & Digital Proofing – Perfecting the Blueprint

Once you’ve selected a partner, the project begins with a crucial alignment phase. This is where you establish a shared understanding and lock in the design before any physical work starts.

The Critical Importance of the Project Kick-Off Call

A professional kick-off call is not just a brief introduction; it’s a formal strategic alignment session. It’s the moment the client’s design team and the model maker’s production team become one single, integrated unit. It’s where the vision is transferred and confirmed.

| The Professional Kick-Off Call Agenda | ||

|---|---|---|

| Item | Purpose | Key Participants |

| Team Introductions | Establish clear roles and a single point of contact (the Project Manager). | Client’s Lead Architect, Model Maker’s Project Manager & Lead Technician. |

| Review of Project Scope & Goals | Confirm the model’s ultimate purpose (e.g., sales, competition, planning). | All. |

| Confirmation of Deliverables | Verify that all necessary CAD files, renderings, and material specs have been received and are usable. | Client’s Architect, Model Maker’s Technician. |

| Deep Dive on Key Details | Discuss specific areas of complexity, such as the desired materials and finishes, and the lighting strategy. | All. |

| Establishing Communication Protocol | Agree on the frequency and format of progress reports (e.g., “photo updates every Friday via email”). | Client’s Lead, Model Maker’s PM. |

| Confirmation of Milestone Dates | Review and agree upon the key dates for client feedback and approval. | All. |

The Digital Proofing Stage: Your Most Powerful Checkpoint

This is arguably the most vital step in the entire remote workflow. Before a single piece of physical material is cut, the model maker will create a complete, meticulously detailed 3D digital model (a “digital twin”) of the final product for your review. This is your opportunity to check every angle, every dimension, every color, and every detail for accuracy from the comfort of your own office. This is the easiest, cheapest, and fastest time to make changes. A professional firm will require a formal, written sign-off on this digital proof before proceeding to fabrication. This creates a clear line of accountability and ensures that what you’ve approved digitally is exactly what you will receive physically.

Phase 3: Production & Monitoring – Radical Transparency from Afar

This is where the physical model comes to life. A professional overseas partner ensures you are intimately involved in this process through a system of radical transparency.

The Weekly Progress Report: Your Window into the Workshop

The weekly progress report is the cornerstone of remote project management. It is a non-negotiable deliverable that keeps you fully informed and in control. A professional report should contain:

- High-Resolution Photographs: Not just one or two, but a comprehensive set of photos from multiple angles, showing both the overall progress and close-ups of detailed work.

- Short Video Clips: A brief video walkthrough can often convey a sense of scale and progress more effectively than static photos.

- A Written Summary: A concise update from your Project Manager detailing what was accomplished that week, what is planned for the next week, and confirming that the project is on schedule.

- A List of Questions: Any points needing your clarification or decision to ensure the project keeps moving forward smoothly.

Material and Finish Verification

How do you ensure the colors and textures are correct from thousands of miles away? A professional firm has a clear process for this. Before applying any finishes, they should send you high-quality photos of the specified materials (e.g., acrylic sheets, wood veneers). For paint colors, they will spray a test piece, photograph it next to the specified Pantone or RAL color chip under neutral lighting, and send it to you for formal approval. This ensures perfect color matching without any guesswork.

Phase 4: Final Approval & Logistics – The Grand Finale

As the project nears completion, the focus shifts to final approval and the critical process of transportation.

The Final Photo & Video Approval Stage

Before the model is touched by any packing material, you should receive a complete set of professional-quality photos and a 360-degree video of the finished, fully assembled, and illuminated product. This is your last chance to review every detail and provide your formal sign-off. This step ensures there are absolutely no surprises when you uncrate the model.

The Science of “Bulletproof” Logistics

Shipping a delicate, high-value item across the world is not a task for amateurs. A professional firm treats logistics as a science. This includes a custom-engineered crate designed specifically for your model, a multi-density foam interior that isolates the model from shock and vibration, meticulous customs documentation to avoid delays, and comprehensive door-to-door insurance. This process is so critical that we have dedicated an entire in-depth guide to it: The Ultimate Guide to Safe International Model Shipping.

Phase 5: Post-Delivery & Support – The Partnership Continues

A great partner’s job isn’t done when the model ships. They support you through the final steps.

The Unpacking and Assembly Process

A professionally shipped model should arrive with a clear, visual guide (often a laminated booklet with photos and a link to a video) on how to safely uncrate and assemble it. This guide will show you how to re-attach any delicate components that were packed separately, like spires or antennas, ensuring a stress-free setup.

Ongoing Support

What if you have a question about the lighting system a week after delivery? A true partner will be available for a video call to guide your team through the setup process and answer any questions about the model’s features long after the invoice is paid. Their goal is your long-term success.

The Linchpin of Success: The Role of the Dedicated Project Manager

If there is one “secret” to flawless overseas project management, it is the quality and empowerment of your dedicated Project Manager (PM). This person is not a salesperson or a simple coordinator; they are your advocate, your translator, and your technical expert inside the model maker’s workshop. They are the single most important factor in ensuring a smooth process.

| Coordinator vs. True Project Manager | ||

|---|---|---|

| Responsibility | A (Passive) Coordinator… | A (Proactive) Project Manager… |

| Communication | Forwards your emails and photos. | Manages a formal communication schedule and translates your intent, not just your words. |

| Problem Solving | Tells you when there is a problem. | Anticipates potential problems and comes to you with proposed solutions. |

| Technical Knowledge | Has a basic understanding of the project. | Can read and interpret complex CAD files and discuss technical fabrication details with you. |

| Client Advocacy | Represents their company’s interests. | Acts as your advocate in the workshop, ensuring your quality standards are met. |

| Reporting | Sends you photos when asked. | Delivers detailed, scheduled progress reports proactively. |

Key Qualities of a World-Class International PM

- Bilingual and Bicultural: They must be fluent not just in your language, but also in the professional culture of architecture and real estate development in your region.

- Technically Proficient: They must be able to read and understand complex architectural drawings (CAD, Revit) and have a deep knowledge of the entire fabrication process, from scale and detail considerations to materials.

- Proactive Problem Solver: The mark of a great PM is that they don’t just report problems; they anticipate them. They see a potential issue with a joint or a material and come to you with a proposed solution before it ever becomes a delay.

Troubleshooting and Risk Mitigation: A Proactive Guide

Even with a perfect process, challenges can arise in any complex project. A professional partner is defined not by the absence of problems, but by the calm, methodical, and transparent way they resolve them. This section addresses the most common client fears head-on.

Scenario 1: “We need to make a design change mid-project.”

The Wrong Way: The firm either flat-out refuses, charges an exorbitant and un-itemized fee, or agrees to the change but implements it incorrectly due to poor communication.

The Professional Way (The Change Order Process): A professional firm has a formal process for this. The Project Manager will pause any relevant work to prevent waste. They will then work with their technical team to assess the impact on the cost and the delivery schedule. They will present you with a clear, concise Change Order document that outlines these impacts. No new work is done, and no extra costs are incurred, until you have formally approved this document. This process is fair, transparent, and protects both parties.

Scenario 2: “We’ve spotted a mistake in a progress photo.”

The Wrong Way: The firm gets defensive. They might deny the error, argue about the interpretation of the drawings, or try to charge you for the correction.

The Professional Way (Ownership and Correction): A great Project Manager will thank you for your diligence in spotting the issue. They will immediately acknowledge the error, confirm the correction needed with their technical team, and assure you it will be fixed. The very next progress report will include clear photos showing that the fix has been implemented perfectly, at their own cost. This demonstrates accountability and a commitment to quality.

Scenario 3: “There’s a potential delay due to a complex technical issue.”

The Wrong Way: Silence. The firm hopes to make up the time and doesn’t tell you about the problem until the deadline has already passed, leaving you in a terrible position.

The Professional Way (Proactive and Transparent Communication): Your Project Manager will inform you of the challenge *the moment it is discovered*. They will explain the issue clearly, outline the plan they are implementing to resolve it, and provide a realistic assessment of any potential impact on the timeline. This proactive communication gives you the maximum amount of time to adjust your own plans if needed and shows respect for you as a partner in the project.

The Digital Toolbox: Technologies That Make Distance Irrelevant

A modern international workflow is powered by a stack of readily available and highly effective digital tools. These technologies are the invisible infrastructure that makes seamless global collaboration possible.

| The International Collaboration Toolkit | ||

|---|---|---|

| Tool Category | Specific Software/Platform | Purpose in the Workflow |

| Real-Time Communication | Zoom, Microsoft Teams, Skype | For face-to-face kick-off meetings, design reviews, and final model presentations. |

| Asynchronous Communication | Email, WhatsApp, WeChat | For formal documentation (email) and quick, informal updates or questions (messaging apps). |

| File Sharing & Management | Dropbox, Google Drive, WeTransfer | To create a single, shared source of truth for all project files, from CAD drawings to progress photos. |

| Digital Design & Review | AutoCAD, Revit, Navisworks, Adobe Acrobat | To create, share, and comment on the technical drawings and 3D digital proofs. |

| Progress Visualization | High-Resolution Digital Photography, 4K Video | To provide crystal-clear visual evidence of the model’s progress and quality at every stage. |

Conclusion: Your New Global Standard

The traditional obstacles of managing an overseas project—communication barriers, lack of quality control, and logistical nightmares—have been systematically solved by the right partners. Through a powerful combination of a robust, transparent process and modern communication technology, distance has truly become irrelevant.

When you choose a partner based on the strength of their process rather than their proximity, you unlock access to a global pool of talent, technology, and value. You are no longer limited by the capabilities of your local market. The “Zero Obstacles” approach is not a distant goal; for the world’s leading architectural and development firms, it is the new professional standard. You can now confidently manage a global project, knowing that perfection is a matter of process, not location.

Ready to Experience a Seamless Global Workflow?

If you’re ready to partner with a team that has perfected the art of international collaboration, we invite you to put our process to the test. Our dedicated project managers are ready to guide you through a seamless, transparent, and world-class model-making experience.