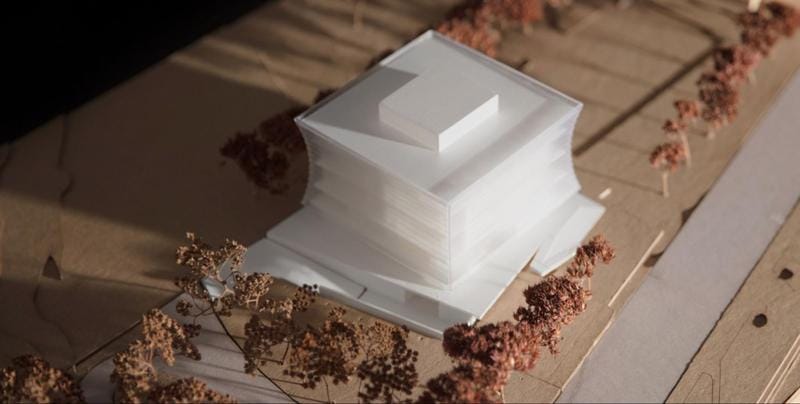

तपाईंको सपनाको भवनको सानो संस्करण होल्ड गर्ने कल्पना गर्नुहोस्, यसको बनावट महसुस गर्दै, र प्रत्येक विवरण नजिकबाट हेर्दै, सबै पहिलो इँटा राख्नु अघि. त्यो वास्तुकला मोडेलहरूको जादू हो! तिनीहरू सधैं डिजाइन प्रक्रियाको आधारशिला भएका छन्, आर्किटेक्टहरूलाई मद्दत गर्दै, ग्राहकहरु, र संलग्न सबैले एउटा परियोजनालाई मूर्त तरिकाले कल्पना गर्छन्. तर के हुन्छ यदि तपाइँ ती मोडेलहरू छिटो बनाउन सक्नुहुन्छ, सस्तो, र पहिले भन्दा धेरै जटिल विवरण संग? थ्रीडी प्रिन्टिङ प्रविष्ट गर्नुहोस् - खेल-परिवर्तक जसले वास्तुविद्हरूले आफ्ना दर्शनहरूलाई जीवनमा कसरी ल्याउने भनेर क्रान्ति गर्दैछ।.

यो गाइड संसारमा गहिरो डुब्छ 3D मुद्रण वास्तुकला मोडेल, यो अत्याधुनिक प्रविधिले कसरी उद्योगलाई रूपान्तरण गरिरहेको छ भनेर प्रकट गर्दै. हामी अविश्वसनीय लाभहरू अन्वेषण गर्नेछौं, तपाईलाई सम्पूर्ण प्रक्रिया मार्फत हिंड्नुहोस्, र वास्तुकलामा 3D मुद्रणको रोमाञ्चक भविष्यमा हेर्नुहोस्. तपाईं आफ्नो डिजाइनहरू उच्च बनाउन र आश्चर्यजनक दृश्यहरू सिर्जना गर्न यो शक्तिशाली उपकरण कसरी प्रयोग गर्न सक्नुहुन्छ भनेर पत्ता लगाउन तयार हुनुहोस्।. सबै मोडेल बनाउने प्रविधिहरू र तिनीहरूका अनुप्रयोगहरूको पूर्ण सिंहावलोकनको लागि, हाम्रो आधारभूत स्तम्भ पृष्ठको साथ सुरू गर्नुहोस्, उच्च-अन्ड आर्किटेक्टल मोडेलहरूको लागि अन्तिम मार्गनिर्देशन.

सामग्रीको तालिका

किन वास्तु मोडेलहरूको लागि 3D मुद्रण छनौट गर्नुहोस्?

आर्किटेक्चरल मोडलिङ को विकास

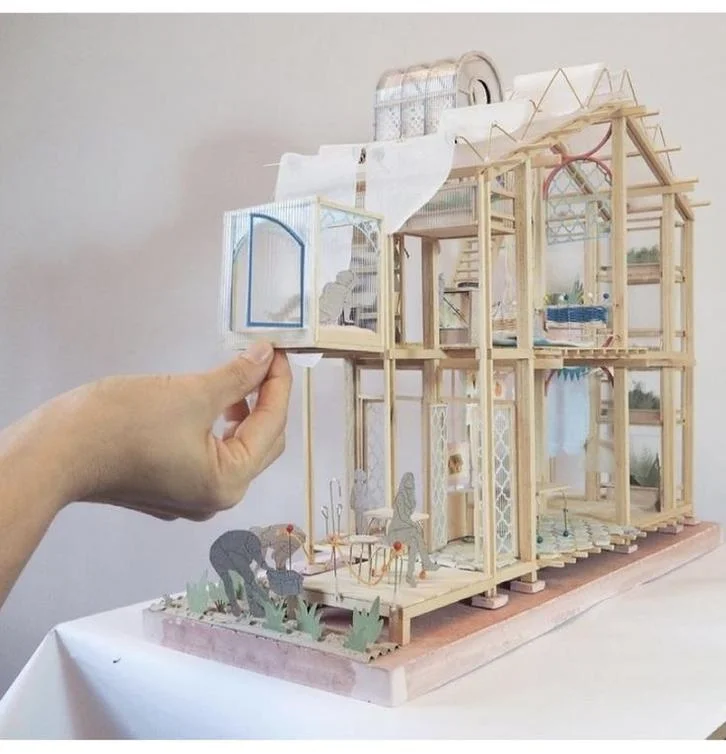

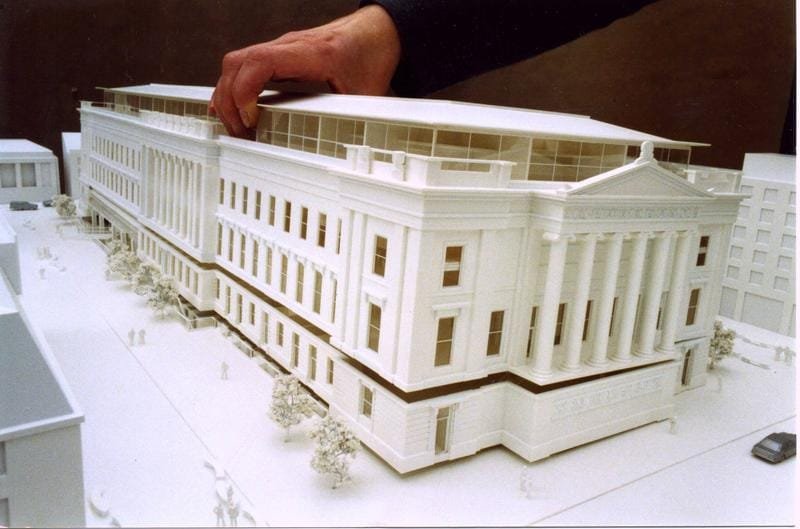

उमेरका लागि, वास्तुकारहरू हातले मोडेलहरू शिल्पमा भर परेका छन्. यसलाई मूर्तिकला जस्तै सोच्नुहोस्, तर साना घरहरु संग! काठ जस्ता सामग्रीहरू प्रयोग गर्दै, शरीरको बाल्ने काम, र गत्ता, दक्ष कारीगरहरूले हप्ताहरू खर्च गर्नेछन्, महिना पनि, सावधानीपूर्वक काट्दै, gluing, र यी लघु संरचनाहरूलाई आकार दिँदै. जबकि सुन्दर, यी हस्तशिल्प मोडेलहरूमा तिनीहरूको कमजोरीहरू थिए. तिनीहरू सुपर समय खपत थिए, आवश्यक विशेष कौशल, र परिवर्तन गर्दै? यसको बारेमा बिर्सनुहोस्! अनुहारमा एक साधारण ट्वीकको अर्थ फेरि सुरु गर्नु हो. जोडेर, त्यो सबै श्रम र सामग्रीको लागत चाँडै जोड्न सक्छ. प्रविधिहरूको यो नाजुक सन्तुलन हामीले हाम्रो गाइडमा अन्वेषण गर्ने कुरा हो आधुनिक शिल्प बनाम. परम्परागत हस्तकला.

3D प्रिन्टिङ अघि वास्तुकला मोडेलहरू कसरी बनाइयो?

3D प्रिन्ट गर्नु अघि, मोडेलहरू दर्दनाक रूपमा हातले क्र्याफ गरिएको थियो. आर्किटेक्ट र मोडेल निर्माताहरूले आरा जस्ता विभिन्न उपकरणहरू प्रयोग गर्नेछन्, चक्कुहरू, र काट्न Sanders, आकार, र जस्ता सामग्रीहरू भेला गर्नुहोस्:

- बाल्सा काठ

- फोम बोर्ड

- दहो कागत

- माटो

- सिरेमिक

यो घटाउने र म्यानुअल प्रक्रिया, आश्चर्यजनक परिणामहरू उत्पादन गर्न सक्षम हुँदा, स्वाभाविक रूपमा ढिलो थियो र पुनरावृत्ति डिजाइन परिवर्तनहरू अत्यन्त गाह्रो र महँगो बनायो.

परम्परागत विधिहरूमा थ्रीडी प्रिन्टिङका फाइदाहरू

अहिले, थ्रीडी प्रिन्टिङले किन वास्तुकला मोडेलको संसारलाई उल्टो बनाउँदैछ भन्ने कुरा गरौं. यो एउटा जादुई छडी भएको जस्तै हो जसले बटनको क्लिकमा जटिल संरचनाहरू बनाउन सक्छ! यसले परम्परागत विधिहरूको लगभग सबै दुखाइ बिन्दुहरूलाई सम्बोधन गर्ने फाइदाहरूको एक सूट प्रदान गर्दछ.

गति र दक्षता

ती हप्ताहरू वा महिनाहरू हातले मोडेलहरू निर्माण गर्न बिताएका सम्झनुहोस्? थ्रीडी प्रिन्टिङको साथ, तपाईंसँग केही घण्टा वा केही दिनमा अत्यधिक विस्तृत मोडेल तयार हुन सक्छ. यी अचम्मका मेसिनहरूले चौबीसै घण्टा पनि काम गर्न सक्छन्, त्यसैले तपाईं साँझमा प्रिन्ट सुरु गर्न सक्नुहुन्छ र समाप्त उत्पादनमा उठ्न सक्नुहुन्छ. यो अविश्वसनीय गति बूस्ट एक कुल खेल-परिवर्तक हो, विशेष गरी जब ग्राहक प्रस्तुतीकरण वा डिजाइन प्रतियोगिताहरूको लागि तंग परियोजना समयसीमा सामना गर्दै.

तपाईं सजिलै 3D मुद्रित वास्तुकला मोडेल परिवर्तन गर्न सक्नुहुन्छ?

प्र्णरुपले! यो थ्रीडी प्रिन्टिङको सबैभन्दा ठूलो लाभ हो. पर्खाल मिलाउन आवश्यक छ, एउटा सञ्झ्याल थप्नुहोस्, वा रूफलाइन परिवर्तन गर्नुहोस्? कुनै समस्या छैन! केवल आफ्नो डिजिटल थ्रीडी फाइल ट्वीक गर्नुहोस्, र तपाईं नयाँ संस्करण छाप्न तयार हुनुहुन्छ. यसले विभिन्न विचारहरू प्रयास गर्न यो सुपर सजिलो र लागत-प्रभावी बनाउँछ, ग्राहक प्रतिक्रिया समावेश, र श्रम र सामाग्री को हप्ता बर्बाद बिना आफ्नो डिजाइन सही.

सटीक र विवरण

तपाईंको डिजाइनको हरेक सानो विवरण क्याप्चर गर्ने कल्पना गर्नुहोस्, जटिल प्यारामेट्रिक अनुहारदेखि नाजुक विन्डो फ्रेमहरू र अलंकृत जालीहरू सम्म. 3डी प्रिन्टिङले सम्भव बनाउँछ! अविश्वसनीय परिशुद्धता संग (अक्सर माइक्रोन मा मापन), यी मेसिनहरूले मोडेलहरू सिर्जना गर्न सक्छन् जुन तपाईंको डिजिटल डिजाइनमा पूर्ण रूपमा वफादार छन्, सबैभन्दा सानो सुविधामा तल. जटिल वक्रहरूको बारेमा सोच्नुहोस्, जैविक आकारहरू, वा यथार्थपरक भौतिक बनावटहरू - परम्परागत ह्यान्ड-क्राफ्टिङ विधिहरूसँग हासिल गर्न साँचो दुःस्वप्न हुने कुराहरू.

डिजाइन लचीलापन र पुनरावृत्ति

विभिन्न छत डिजाइन वा विन्डो प्लेसमेन्ट प्रयोग गर्न चाहनुहुन्छ? 3डी प्रिन्टिङले यसलाई हावा बनाउँछ! तपाईं चाँडै आफ्नो मोडेल को धेरै संस्करणहरू सिर्जना गर्न सक्नुहुन्छ, उडान मा ट्वीक डिजाइन, र धेरै ठोस विकल्पहरू साथ-साथै ग्राहकहरूलाई प्रस्तुत गर्नुहोस्. यो विभिन्न विचारहरू अन्वेषण गर्न र निर्माण सुरु हुनु अघि तिनीहरूको डिजाइनहरू सिद्ध गर्न चाहने आर्किटेक्टहरूका लागि ठूलो फाइदा हो।. स्क्र्याचबाट सुरु गर्नु पर्ने डरलाग्दो भावना बिना ग्राहक प्रतिक्रिया समावेश गर्नको लागि यो उत्कृष्ट छ।.

लागत-प्रभावकारिता

जबकि व्यावसायिक-ग्रेड 3D प्रिन्टरमा प्रारम्भिक लगानी उच्च देखिन्छ, दीर्घकालीन लागत बचत महत्वपूर्ण छ. यसको बारेमा सोच्नुहोस्: म्यानुअल श्रममा भारी कमी, न्यूनतम सामग्री अपशिष्ट (यो एक additive प्रक्रिया हो), र डिजाइनहरूमा द्रुत रूपमा पुनरावृत्ति गर्ने क्षमताले ठूलो बचतमा जोड दिन्छ. जोडेर, धेरै थ्रीडी प्रिन्टिङ सामग्रीको कच्चा लागत प्रायः परम्परागत मोडेल निर्माणमा प्रयोग हुने विशेष काठ र एक्रिलिकहरू भन्दा बढी किफायती हुन्छ।. कसरी टेक्नोलोजीले मूल्यलाई असर गर्छ भन्ने पूर्ण विच्छेदको लागि, हाम्रो गाईड हेर्नुहोस् द 5 वास्तुकला मोडेल मूल्य निर्धारण को मुख्य कारक.

परिष्कृत संचार र सहयोग

कहिल्यै जटिल व्याख्या गर्ने प्रयास गरे, केवल 2D रेखाचित्र प्रयोग गरेर त्रि-आयामी डिजाइन? यो कठिन हुन सक्छ! थ्रीडी प्रिन्टेड मोडेलले सञ्चारलाई धेरै सजिलो बनाउँछ. यसले तपाइँको परियोजनाको मूर्त प्रतिनिधित्व प्रदान गर्दछ जुन जो कोहीले उठाउन सक्छ, घुमाउनुहोस्, र सहज रूपमा बुझ्नुहोस्. यो साझा समझले वास्तुकारहरू बीच राम्रो सहयोगको नेतृत्व गर्न सक्छ, ईन्जिनियरहरू, र ग्राहकहरु, कम गलतफहमी र सहजताको परिणाम, अधिक कुशल डिजाइन प्रक्रिया.

थ्रीडी प्रिन्टिङ वास्तुकला मोडेलका फाइदाहरू के हुन्??

यहाँ उत्कृष्ट लाभहरूको द्रुत रिक्याप छ:

| फाइदा | वर्णन |

|---|---|

| चाल & कार्यकुशलता | हफ्ता देखि घण्टा सम्म मोडेल निर्माण समय एकदम घटाउँछ, द्रुत प्रोटोटाइप सक्षम गर्दै. |

| यथार्थता & बेहोरा | जटिल डिजाइनहरू क्याप्चर गर्दछ, जटिल ज्यामिति, र उच्च शुद्धता संग राम्रो सुविधाहरू. |

| डिजाइन लचीलापन | सजिलोको लागि अनुमति दिन्छ, कम लागत परिमार्जन र धेरै डिजाइन पुनरावृत्ति परिणाम सिद्ध गर्न. |

| लागत-प्रभावकारिता | म्यानुअल श्रम लागत र भौतिक अपशिष्ट घटाउँछ, महत्त्वपूर्ण दीर्घकालीन बचतको लागि अग्रणी. |

| बृद्धि भएको संचार | सबै परियोजना सरोकारवालाहरू बीच समझ र सहयोग सुधार गर्दछ, ग्राहक देखि निर्माणकर्ता सम्म. |

सामग्री बहुमुखी प्रतिभा

3डी प्रिन्टिङ एक-साइज-फिट-सबै समाधान होइन. तपाईंसँग विकल्पहरू छन्! ABS जस्ता बलियो प्लास्टिक देखि खाली र विस्तृत रेजिन सम्म, त्यहाँबाट छनौट गर्न सामग्रीको एक विस्तृत श्रृंखला छ. यसको मतलब तपाइँ तपाइँको परियोजना को विशिष्ट आवश्यकताहरु को लागी उत्तम सामग्री चयन गर्न सक्नुहुन्छ, चाहे तपाईलाई संरचनात्मक मोडेलको लागि टिकाऊ केहि चाहिन्छ वा निर्दोषको साथ केहि, अन्तिम प्रस्तुति टुक्राको लागि चिकनी समाप्त. तपाईं आफ्नो मोडेल साँच्चै बाहिर खडा बनाउन विभिन्न रङ र बनावट संग प्रयोग गर्न सक्नुहुन्छ. हामी हाम्रो मा विस्तृत रूपमा यो विषय अन्वेषण मोडेल सामग्री र फिनिशहरूको लागि गाइड.

वास्तुकला मोडेलहरूको लागि 3D प्रिन्टिङ टेक्नोलोजीका प्रकारहरू

ठीक छ, त्यसैले तपाईं थ्रीडी प्रिन्टिङका फाइदाहरूमा बेचिनुहुन्छ. तर त्यहाँ धेरै फरक प्रविधिहरूसँग, तपाइँ तपाइँको वास्तुकला मोडेल को लागी सही एक कसरी छनौट गर्नुहुन्छ? पेशेवरहरूले प्रयोग गर्ने सबैभन्दा लोकप्रिय विकल्पहरू तोडौं.

स्टीरियोथिकमूल्यिकरण (ित)

तरल रालको पोखरीमा तपाईंको डिजाइनलाई सावधानीपूर्वक कोरेको लेजर बीमको कल्पना गर्नुहोस्, सावधानीपूर्वक तहद्वारा यसलाई कडा बनाउँदै. त्यो संक्षेपमा SLA हो! यो प्रविधिले निको पार्न यूभी लेजर प्रयोग गर्छ, वा कडा, तरल photopolymer राल, सुपर चिकनी सतहहरूको साथ अविश्वसनीय रूपमा विस्तृत र सही मोडेलहरू सिर्जना गर्दै. यो जादू जस्तै छ, तर विज्ञान संग! यदि तपाईंलाई क्लाइन्ट प्रस्तुतीकरणको लागि जटिल विवरणहरू र निर्दोष समाप्त भएको मोडेल चाहिन्छ - तपाईंलाई मद्दत गर्न सक्ने मोडेलको प्रकार तपाईंको सम्पत्ति बिक्री डबल गर्नुहोस्-SLA एक शानदार विकल्प हो. जोडेर, त्यहाँ अब छिटो रेजिन र ठूलो-ढाँचा SLA प्रिन्टरहरू उपलब्ध छन्, यसलाई अझ बहुमुखी बनाउन. ठूलो ढाँचा SLA प्रिन्टरको एउटा उदाहरण हो Formlabs बाट फारम 3L.

फ्यूज डिस्पोजिन मोडेलिंग (एफडीजी) / फ्यूज्ड फिलामेन्ट निर्माण (FFF)

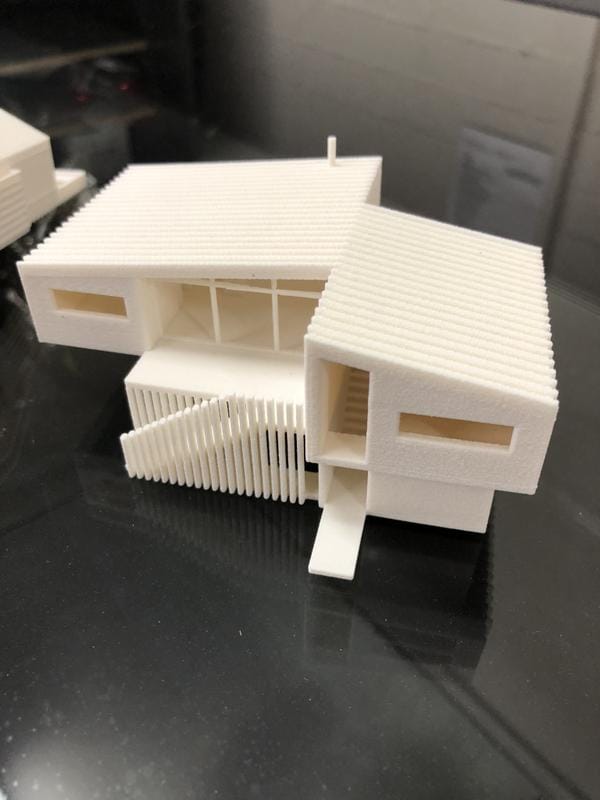

FDM लाई हाई-टेकको रूपमा सोच्नुहोस्, कम्प्युटर-नियन्त्रित तातो गोंद बन्दूक. यसले थर्मोप्लास्टिक फिलामेन्ट पग्लेर र बाहिर निकालेर काम गर्छ (प्लास्टिक स्ट्रिङ को एक स्पूल), तहमा तह, आफ्नो मोडेल निर्माण गर्न. यो प्लाष्टिकका स-साना स्ट्रेन्डहरूले निर्माण गर्नु जस्तै हो! FDM थ्रीडी प्रिन्टिङको सबैभन्दा सामान्य र किफायती प्रकार हो, प्रारम्भिक-चरण अवधारणा मोडेलहरू वा ठूला मोडेलहरू सिर्जना गर्ने वास्तुविद्हरूको लागि यसलाई लोकप्रिय छनोट बनाउँदै जहाँ सुपर-फाईन सतह विवरणहरू शीर्ष प्राथमिकतामा पर्दैन।. जबकि रिजोलुसन SLA जत्तिकै उच्च नहुन सक्छ, FDM एक भरपर्दो र लागत प्रभावी workhorse हो.

चयनकर्ता लेजर पास्टर (घुस)

SLS SLA को पाउडर-आधारित कजिन जस्तै हो. तरल राल को सट्टा, यसले पोलिमर पाउडरको स-साना कणहरूलाई एकसाथ फ्यूज गर्न उच्च-शक्तियुक्त लेजर प्रयोग गर्दछ, सामान्यतया नायलन, तह द्वारा तह. SLS को बारेमा के राम्रो छ कि वरपरको अनफ्यूज पाउडरले मुद्रणको समयमा मोडेललाई समर्थन गर्दछ, त्यसैले यसलाई अलग समर्थन संरचना आवश्यक छैन. यसले आन्तरिक सुविधाहरू वा अन्डरकटहरूको साथ अत्यधिक जटिल ज्यामितिहरू सिर्जना गर्न यो आदर्श बनाउँछ. जोडेर, नायलन मोडेल बलियो र टिकाउ छन्, तिनीहरूलाई कार्यात्मक वा संरचनात्मक भागहरूको लागि उपयुक्त बनाउन. यदि तपाईंलाई जटिल आन्तरिक विवरणहरूको साथ बलियो मोडेल चाहिन्छ, SLS जाने बाटो हुन सक्छ.

BInder जुटेको

Binder Jetting गुच्छा मध्ये एक रंगीन हो! यसले रंगीन बाइन्डिङ एजेन्ट जम्मा गरेर काम गर्छ (गोंद जस्तै) इन्कजेट-शैली प्रिन्टहेडबाट पाउडरको तहमा, यसलाई ठोस गर्दै. प्रक्रिया तह द्वारा तह दोहोर्याउँछ, प्रिन्टरबाटै पूर्ण-रङ मोडेल सिर्जना गर्दै. जबकि Binder Jetting जीवन्त बनाउन को लागी शानदार छ, आँखा आकर्षक मोडेलहरू, यसमा केही सीमितताहरू छन्. मोडेलहरू अन्य प्रविधिहरूको तुलनामा अधिक छिद्रपूर्ण र भंगुर हुन्छन्, तिनीहरूलाई कार्यात्मक प्रोटोटाइपहरू भन्दा स्थिर प्रदर्शन मोडेलहरूको लागि अझ राम्रो बनाउन. Binder Jetting प्रिन्टरहरूको एक अग्रणी निर्माता हो 3डी प्रणाली.

वास्तुकला मोडेलहरूको लागि उत्तम 3D मुद्रण प्रविधि के हो?

सत्य कुरा हो, त्यहाँ कुनै एकल छैन “सबभन्दा रामो” शिल्पविज्ञान. यो सबै आफ्नो विशिष्ट आवश्यकता मा निर्भर गर्दछ! तपाईंलाई निर्णय गर्न मद्दत गर्नको लागि यहाँ द्रुत तुलना छ:

| शिल्पविज्ञान | संकल्प | परिशुद्घता | सतह समाप्त | को लागी सबै भन्दा राम्रो |

|---|---|---|---|---|

| ित | ★★★★★ | ★★★★★ | ★★★★★ | चिल्लो सतहहरु संग उच्च विस्तृत प्रस्तुतीकरण मोडेल. |

| FDM/FFF | ★★☆☆☆ | ★★★★☆ | ★★☆☆☆ | आधारभूत अवधारणा मोडेलहरू, ठूलो मासिंग मोडेलहरू, प्रारम्भिक पुनरावृत्ति. |

| घुस | ★★★★☆ | ★★★★★ | ★★★★☆ | आन्तरिक विशेषताहरु संग जटिल ज्यामिति, टिकाऊ संरचनात्मक भागहरू. |

| BInder जुटेको | ★★★☆☆ | ★★★☆☆ | ★★★☆☆ | स्थिर प्रदर्शनका लागि पूर्ण-रङ अवधारणात्मक वा प्रस्तुतीकरण मोडेलहरू. |

थ्रीडी प्रिन्टिङ वास्तुकला मोडेलहरूको लागि चरण-दर-चरण गाइड

तपाईंको वास्तुकला दृष्टिलाई मूर्त 3D मुद्रित वास्तविकतामा बदल्न तयार छ? व्यावसायिक प्रक्रिया मार्फत हिंडौं, चरणबद्ध रूपमा:

अवधारणात्मक डिजाइन र योजना

प्रत्येक महान परियोजना एक ठोस आधार संग सुरु हुन्छ. तपाईंले आफ्नो 3D मोडलिङ सफ्टवेयर छुनु अघि, विचार गर्न केहि समय लिनुहोस्, प्रेरणा सङ्कलन, र वास्तवमै परियोजना आवश्यकताहरू बुझ्नुहोस्. मोडेल को उद्देश्य के हो? दर्शक को हो? तपाईले हाइलाइट गर्न चाहनुहुने मुख्य विशेषताहरू के हो? स्पष्ट दृष्टिले तपाईंलाई सम्पूर्ण प्रक्रिया मार्फत मार्गदर्शन गर्नेछ. यो त्यो चरण हो जहाँ तपाईं पनि सोच्न थाल्नुहुन्छ स्केल र विवरणको सही सन्तुलन खोज्दै आफ्नो परियोजना को लागी.

डिजिटल थ्रीडी मोडलिङ

अब यो तपाईंको डिजाइनलाई डिजिटल संसारमा जीवनमा ल्याउने समय हो! कम्प्युटर-सहायता डिजाइन प्रयोग गर्दै (कार्यवाह) सल्लो सफ्टवेयर, तपाईंले आफ्नो वास्तु परियोजनाको विस्तृत 3D प्रतिनिधित्व सिर्जना गर्नुहुनेछ. यसलाई तपाइँको मोडेलको भर्चुअल संस्करण निर्माणको रूपमा सोच्नुहोस्, टुक्रा टुक्रा.

थ्रीडी मुद्रित वास्तुकला मोडेलहरू डिजाइन गर्न कुन सफ्टवेयर प्रयोग गरिन्छ?

त्यहाँ धेरै उत्कृष्ट विकल्पहरू छन्, प्रत्येकको आफ्नै शक्ति संग. यहाँ आर्किटेक्टहरू बीच केही लोकप्रिय विकल्पहरू छन्:

- Autocad: 2D ड्राफ्टिङ र 3D डिजाइनिङको लागि क्लासिक, यसले सटीक नियन्त्रणलाई आयाम र ज्यामिति भन्दा बढी प्रदान गर्दछ.

- पुनर्जय दिनु: जानकारी मोडलिंगको लागि विशेष रूपमा डिजाइन गरिएको (बिमले पैर), यसले तपाईंलाई सम्बन्धित led संरचनाहरू सम्बद्ध डाटाको साथ थकित 3D संरचनाहरू सिर्जना गर्न अनुमति दिन्छ.

- गैंडा (गैंडा): यसको बहुमुखीताको लागि परिचित, गैंडा जटिल र जैविक फारामहरू सिर्जना गर्न ठूलो छ, प्राय: प्यारामिटर मोडिंगको लागि ग्राउट प्लगइनसँग प्रयोग गरियो.

- स्केचअप: प्रयोगकर्ता-मैत्री र सहज, यो द्रुत अवधारणा मोडेलिंग र दृश्यकरणको लागि लोकप्रिय विकल्प हो.

- चम्करण: उन्नत मूर्तिकला र प्रतिपादन क्षमताहरूको साथ एक शक्तिशाली खुला स्रोत उपकरण, प्रायः अवधारणात्मक मोडलिङको लागि प्रयोग गरिन्छ.

जुन सफ्टवेयर तपाईले रोज्नुहुन्छ, दिमागमा थ्रीडी प्रिन्टिङको साथ डिजाइन गर्न सम्झनुहोस्. यसको अर्थ सिर्जना गर्नु हो “वाटरटाइट” मोडेलहरू (तलको बारेमा थप) र पर्खाल मोटाई र समर्थन संरचना जस्ता कारकहरू विचार गर्दै.

3D प्रिन्टिङको लागि मोडेल तयारी

तपाईंले त्यो हिट गर्नु अघि “छाप्नुहोस्” बटन, तपाइँले तपाइँको डिजिटल मोडेल यसको 3D प्रिन्टिङ डेब्यूको लागि तयार छ भनेर सुनिश्चित गर्न आवश्यक छ. यसले केही महत्त्वपूर्ण चरणहरू समावेश गर्दछ:

स्केल रूपान्तरण

अधिकांश वास्तुकला डिजाइनहरू ए मा सिर्जना गरिन्छ 1:1 स्केल, यसको अर्थ तिनीहरूले भवनको वास्तविक आकारलाई प्रतिनिधित्व गर्छन्. तर तपाईंको 3D प्रिन्टेड मोडेल धेरै सानो हुनेछ! तपाईंले आफ्नो डिजाइनलाई इच्छित मोडेल स्केलमा रूपान्तरण गर्न आवश्यक छ, जस्तै 1:50, 1:100, अथवा 1:200. यसले सुनिश्चित गर्दछ कि तपाइँको मोडेल तपाइँको आवश्यकताहरु को लागी सही साइज हो र तपाइँको प्रिन्टरको निर्माण भोल्युम भित्र फिट हुन्छ.

मोडेल अनुकूलन

यो जहाँ तपाईं एक 3D मुद्रण जासूस बन्छ, मुद्रण प्रक्रियालाई असर गर्न सक्ने सम्भावित समस्याहरू खोज्दै. हेर्नु पर्ने कुरा यहाँ छ:

- ओभरह्याङ्ग्स: यी तपाईंको मोडेलका भागहरू हुन् जुन कुनै पनि समर्थन बिना तल बाहिर विस्तार हुन्छ. अत्याधिक ओभरह्याङले ड्रपिङ वा प्रिन्टिङ विफलता निम्त्याउन सक्छ.

- असमर्थित भागहरू: overhangs जस्तै, यी क्षेत्रहरू छन् जुन पर्याप्त रूपमा समर्थित छैनन् र मुद्रणको समयमा पतन हुन सक्छ.

- अत्यधिक जटिलता: जबकि थ्रीडी प्रिन्टिङले जटिल विवरणहरू ह्यान्डल गर्न सक्छ, अत्यधिक जटिल मोडेलहरू छाप्न चुनौतीपूर्ण हुन सक्छ र महत्त्वपूर्ण पोस्ट-प्रोसेसिङ आवश्यक हुन सक्छ.

3D प्रिन्टिङको लागि म कसरी मेरो वास्तुकला मोडेल तयार गर्छु?

यहाँ तपाइँको मोडेल अनुकूलन गर्न केहि प्रविधिहरू छन्:

- मोडेलहरूलाई भागहरूमा विभाजन गर्दै: यदि तपाईंको मोडेल धेरै ठूलो वा जटिल छ, यसलाई सानोमा तोड्ने विचार गर्नुहोस्, थप व्यवस्थित खण्डहरू जुन छुट्टै छाप्न सकिन्छ र पछि जम्मा गर्न सकिन्छ. यो विशेष गरी महत्त्वपूर्ण छ जब हाम्रो मा कभर रसद बारे सोच प्याकेजिङ र ढुवानी मोडेलहरूको लागि गाइड.

- विधानसभा लागि डिजाइन: मोडेल विभाजन गर्दा, भागहरू कसरी एकसाथ फिट हुनेछ भनेर सोच्नुहोस्. मिलन सुविधाहरू थप्दै, इन्टरलकिङ ट्याब वा स्लटहरू जस्तै, सभालाई हावा बनाउन सक्छ. तपाईं पनि seams वा व्यक्तिगत घटक द्वारा मोडेल विभाजित गर्न सक्नुहुन्छ.

- वाटरटाइट मोडेलहरू सुनिश्चित गर्दै: यो महत्त्वपूर्ण छ! एक वाटरटाइट (वा धेरै गुणा) मोडेल यसको डिजिटल सतहमा कुनै प्वाल वा खाली ठाउँ बिना सिल गरिएको कन्टेनर जस्तै हो. तपाईंको 3D मोडलिङ सफ्टवेयरमा कुनै त्रुटिहरू जाँच गर्न र समाधान गर्न उपकरणहरू छन्. तिनीहरूलाई प्रयोग गर्नुहोस्!

- उपयुक्त पर्खाल मोटाई छनोट: धेरै पातलो पर्खालहरू नाजुक हुन सक्छन् र प्रिन्ट गर्दा वाप्न वा भाँच्न सक्छन्. सुनिश्चित गर्नुहोस् कि तपाईंको पर्खालहरू संरचनात्मक अखण्डता प्रदान गर्न पर्याप्त बाक्लो छन्, विशेष गरी मोडेल को आधार मा.

फाइल निर्यात

एक पटक तपाईंको मोडेल अनुकूलित हुन्छ, यो तपाईंको 3D प्रिन्टरले बुझ्न सक्ने ढाँचामा निर्यात गर्ने समय हो. 3D प्रिन्टिङका लागि सबैभन्दा सामान्य फाइल ढाँचाहरू STL हुन् (स्टीरियोथिकमूल्यिकरण) र OBJ (वस्तु फाइल). यी ढाँचाहरूले अनिवार्य रूपमा तपाइँको मोडेलको सतह ज्यामितिलाई त्रिकोणको जालको रूपमा वर्णन गर्दछ, सामग्री कहाँ जम्मा गर्ने भनेर प्रिन्टरलाई बताए.

सही थ्रीडी प्रिन्टिङ टेक्नोलोजी र सामग्री छनोट गर्दै

सही थ्रीडी प्रिन्टिङ टेक्नोलोजी र सामग्री छनोट गर्दै

हामीले पहिले नै विभिन्न प्रकारका थ्रीडी प्रिन्टिङ प्रविधिहरू समावेश गरिसकेका छौं, तर आफ्नो छनौट गर्दा विचार गर्नुपर्ने मुख्य कारकहरूलाई दोहोर्याउनुहोस्:

- विवरण आवश्यकताहरू: तपाईको मोडेल कत्तिको जटिल हुनु आवश्यक छ? SLA उच्च विवरणको लागि उत्कृष्ट छ, जबकि FDM ठूलो को लागी राम्रो छ, कम विस्तृत मोडेलहरू.

- बजेट: FDM सामान्यतया सबैभन्दा किफायती विकल्प हो, जबकि SLA र SLS महँगो हुन सक्छ.

- मोडेल उद्देश्य: यो एक ग्राहक प्रस्तुतीकरण को लागी हो, संरचनात्मक विश्लेषण, वा द्रुत अवधारणा मोडेल?

थ्रीडी प्रिन्ट वास्तुकला मोडेलहरूमा कुन सामग्रीहरू प्रयोग गरिन्छ?

तपाईंले छनौट गर्नुभएको सामग्रीले लुकलाई असर गर्नेछ, अनुभव गर्नु, र तपाईंको मोडेलको स्थायित्व. यहाँ केहि लोकप्रिय विकल्पहरूमा नजिकको नजर छ:

| भौतिक | वर्णन | लाभ | बिप्ति |

|---|---|---|---|

| वीट (Polylactic एसिड) | मकैको स्टार्चबाट व्युत्पन्न बायोडिग्रेडेबल थर्मोप्लास्टिक. | प्रयोग गर्न सजिलो, किन्युखादार, रङहरूको फराकिलो दायरा, विस्तृत मोडेलहरूको लागि राम्रो. | ABS भन्दा कम टिकाउ र गर्मी प्रतिरोधी; भंगुर हुन सक्छ. |

| ए (Acrylonitrile Butadiene Styrene) | सामान्य थर्मोप्लास्टिक यसको बल र स्थायित्वको लागि चिनिन्छ. | PLA भन्दा बलियो र अधिक गर्मी प्रतिरोधी, कार्यात्मक मोडेलहरूको लागि राम्रो. | प्रिन्ट गर्दा वार्पिङको सम्भावना, तातो प्रिन्ट बेड चाहिन्छ. |

| राल | तरल फोटोपोलिमर SLA प्रिन्टरहरूमा UV प्रकाश द्वारा निको हुन्छ. | अत्यन्त उच्च रिजोलुसन, चिल्लो सतह समाप्त, जटिल विवरणहरूको लागि आदर्श. | PLA वा ABS भन्दा महँगो, सावधानीपूर्वक ह्यान्डलिङ र पोस्ट-क्युरिङ आवश्यक छ. |

| नायलन (पोलिमाइड) | SLS प्रिन्टरहरूमा प्रयोग गरिएको बलियो र टिकाउ प्लास्टिक पाउडर. | उत्कृष्ट शक्ति र स्थायित्व, थोरै लचिलो, संरचनात्मक भागहरूको लागि राम्रो. | उच्च मुद्रण तापमान आवश्यक छ, यदि राम्ररी भण्डारण गरिएको छैन भने नमी अवशोषित गर्न सक्छ. |

स्लाइसिङ र प्रिन्ट सेटिङहरू

तपाईंको थ्रीडी प्रिन्टरले यसको जादू काम गर्न सुरु गर्नु अघि, यसलाई निर्देशनहरूको विस्तृत सेट चाहिन्छ. त्यो जहाँ स्लाइसिङ सफ्टवेयर आउँछ. यो सफ्टवेयरले तपाइँको 3D मोडेल लिन्छ र यसलाई सयौं वा हजारौं पातलोमा डिजिटल रूपमा स्लाइस गर्दछ, तेर्सो तहहरू, G-कोड उत्पन्न गर्दै जसले प्रिन्टरलाई कसरी सार्ने र प्रत्येक तहको लागि सामग्री कहाँ जम्मा गर्ने भनेर बताउँछ.

थ्रीडी प्रिन्टिङमा स्लाइसिङ के हो?

स्लाइसिङ भनेको तपाईको थ्रीडी प्रिन्टरको लागि पालैपालो रोडम्याप बनाउनु जस्तै हो. यसले तपाइँको जटिल 3D मोडेललाई सरल श्रृंखलामा विभाजन गर्दछ, प्रिन्टरले पछ्याउन सक्ने दुई-आयामी निर्देशनहरू, तह द्वारा तह. लोकप्रिय स्लाइसिङ सफ्टवेयर विकल्पहरू समावेश छन्:

- अल्टिमेकर क्युरा: एक नि: शुल्क, प्रयोगकर्ता-अनुकूल स्लाइसर जुन शुरुआती र पेशेवरहरूको लागि उत्कृष्ट छ.

- PrusaSlicer: अर्को नि: शुल्क र खुला स्रोत विकल्प, यसको उन्नत सुविधाहरू र बलियो समुदाय समर्थनको लागि परिचित.

- सरलीकरण 3D: शक्तिशाली अनुकूलन विकल्पहरूको साथ सशुल्क सफ्टवेयर, प्राय: पेशेवरहरूले समर्थन संरचनाहरूमा यसको नियन्त्रणको लागि रुचाउँछन्.

स्लाइसिङ सफ्टवेयर भित्र, तपाईंले मुद्रण प्रक्रियालाई अनुकूलन गर्न विभिन्न मुद्रण सेटिङहरू समायोजन गर्न आवश्यक छ. यहाँ विचार गर्न केही प्रमुख सेटिङहरू छन्:

- तह उचाइ: यसले प्रत्येक तहको मोटाई निर्धारण गर्दछ. तल्लो तह उचाइ (E.g, 0.1mm) राम्रो विवरण र चिल्लो सतहहरूमा परिणामहरू तर उल्लेखनीय रूपमा लामो प्रिन्ट समय. वास्तुकला मोडेल को लागी, तल्लो तह उचाइ प्राय: विस्तृत भागहरूको लागि प्रयोग गरिन्छ, जबकि मोटो उचाइ (0.2मिमी वा बढी) कम विस्तृत खण्डहरूको छिटो प्रिन्टहरूको लागि प्रयोग गर्न सकिन्छ.

- मुद्रण गति: यसले सामग्री बाहिर निकाल्दा प्रिन्टरको नोजल कति छिटो सर्छ भन्ने नियन्त्रण गर्छ. ढिलो गतिले सामान्यतया राम्रो प्रिन्ट गुणस्तर र शुद्धतामा परिणाम दिन्छ, जुन विशेष गरी जटिल मोडेलहरूको लागि महत्त्वपूर्ण छ.

- समर्थन गर्दछ: यी अस्थायी हुन्, जाली-जस्तै संरचनाहरू जसले ओभरह्याङ्गहरू समात्छन् र मुद्रणको समयमा तिनीहरूलाई भत्काउनबाट रोक्छन्. तपाईंको स्लाइसिङ सफ्टवेयरले स्वचालित रूपमा समर्थनहरू उत्पन्न गर्न सक्छ, तर तपाईं म्यानुअल रूपमा तिनीहरूको स्थान र घनत्व समायोजन गर्न सक्नुहुन्छ. सम्झनुहोस्, समर्थन पोस्ट-प्रोसेसिङ समयमा सावधानीपूर्वक हटाउन आवश्यक हुनेछ, त्यसैले सम्भव भएसम्म तिनीहरूको प्रयोगलाई न्यूनीकरण गर्न आफ्नो मोडेललाई उन्मुख गर्नु राम्रो विचार हो.

3D मोडेल प्रिन्ट गर्दै

तपाइँको मोडेल काटिएको र तपाइँको प्रिन्ट सेटिङहरूमा डायल गरिएको छ, यो अन्ततः हिट गर्न समय हो “छाप्नुहोस्” बटन! 3D प्रिन्टरले अब तपाइँको मोडेल निर्माण सुरु गर्नेछ, तह द्वारा तह, स्लाइसिङ सफ्टवेयर द्वारा उत्पन्न G-कोड अनुसरण गर्दै. आकार मा निर्भर गर्दछ, जटिलता, र तपाईंको मोडेलको तह उचाइ, यो प्रक्रिया केहि घण्टा देखि धेरै दिन सम्म लाग्न सक्छ.

तपाईंको प्रिन्टरमा नजर राख्नु राम्रो विचार हो, विशेष गरी महत्त्वपूर्ण पहिलो केही तहहरूमा, प्रिन्ट बेडमा सबै कुरा राम्ररी पालना गरिरहेको छ भनी सुनिश्चित गर्न. यदि तपाइँ कुनै समस्याहरू देख्नुहुन्छ भने, जस्तै वार्पिङ वा खराब आसंजन, तपाईंले प्रिन्ट रोक्न आवश्यक हुन सक्छ, आफ्नो सेटिङहरू समायोजन गर्नुहोस्, र फेरि सुरु गर्नुहोस्.

पोस्ट-प्रोसेसिङ

एक पटक तपाईंको मोडेल मुद्रण समाप्त भएपछि, यो यसको क्लोज-अपको लागि पूर्ण रूपमा तयार छैन. धेरै जसो थ्रीडी प्रिन्टेड मोडेलहरूलाई समर्थनहरू हटाउन केही डिग्री पोस्ट-प्रोसेसिङ चाहिन्छ, चिल्लो बाहिर सतहहरू, र एक पेशेवर समाप्त लागि आफ्नो उपस्थिति वृद्धि.

तपाइँ कसरी 3D मुद्रित वास्तुकला मोडेल समाप्त गर्नुहुन्छ?

यहाँ केहि सामान्य पोस्ट-प्रोसेसिङ प्रविधिहरू छन्:

- समर्थन हटाउने: यदि तपाइँको मोडेल समर्थन संग छापिएको थियो, तपाईंले चिमटा प्रयोग गरेर तिनीहरूलाई सावधानीपूर्वक हटाउन आवश्यक छ, फ्लश कटरहरू, वा अन्य साना उपकरणहरू. धैर्य हुनुहोस् र मोडेलको नाजुक भागहरू तोड्नबाट बच्न आफ्नो समय लिनुहोस्.

- Sanding र Smoothing: फाइन-ग्रिट स्यान्डपेपरको साथ स्यान्डिङले कुनै नराम्रो किनारा वा देखिने तह रेखाहरूलाई चिल्लो बनाउन मद्दत गर्न सक्छ।. PLA र ABS प्रिन्टहरूको लागि, तपाईं एक चमकदार फिनिश प्राप्त गर्न एसीटोन भाप स्मूथिंग पनि प्रयोग गर्न सक्नुहुन्छ. यो उन्नत प्रविधिले एसीटोन वाष्पमा मोडेललाई उजागर गर्ने समावेश गर्दछ, जसले बाहिरी सतहलाई अलिकति पग्लन्छ, एक चिकनी सिर्जना, चमकदार उपस्थिति.

- प्राइमिङ र पेन्टिङ: पेन्टिङ गर्नु अघि उच्च गुणस्तरको मोडेल प्राइमर लागू गर्नाले पेन्टलाई राम्रोसँग टाँस्न र एक समान सतह सिर्जना गर्न मद्दत गर्छ।. त्यसपछि तपाइँ तपाइँको मोडेलमा रंग र विवरण थप्न एयरब्रश वा राम्रो ब्रश संग एक्रिलिक रंग प्रयोग गर्न सक्नुहुन्छ. अन्तमा, पेन्ट सुरक्षित गर्न र पालिश दिन स्पष्ट कोटहरू लागू गर्न सकिन्छ, व्यावसायिक रूप.

- बन्धन: यदि तपाईंले आफ्नो मोडेल धेरै भागहरूमा छाप्नुभयो भने, तपाईंले तिनीहरूलाई सँगै बन्धन गर्न आवश्यक छ. Cyanoacrylate (सुपर ग्लुहरू) वा विशेष तरल रेजिन सामान्यतया यस उद्देश्यको लागि प्रयोग गरिन्छ.

| पोस्ट प्रशोधन प्रविधि | ित | एफडीजी | घुस | बाइन्डर जेटिंग |

|---|---|---|---|---|

| चालू | समर्थन चिन्हहरू हटाउन हल्का स्यान्डिङ सिफारिस गरिन्छ. | स्यान्डिङ अक्सर एक चिकनी फिनिश प्राप्त गर्न र तह रेखाहरू हटाउन आवश्यक छ. | समाप्त भागहरूको गुणस्तरको कारणले कुनै स्यान्डिङ आवश्यक छैन. | कुनै sanding आवश्यक छैन. |

| बन्धन | SLA कम्पोनेन्टहरूको बन्धन सुपर ग्लु वा बढी तरल रालको साथ गरिन्छ. | FDM कम्पोनेन्टहरू सुपर ग्लु जस्ता चिपकाउने प्रयोग गरेर भेला गर्न सकिन्छ. | एसएलएस कम्पोनेन्टहरू सुपर ग्लु जस्ता चिपकाउने प्रयोग गरेर भेला गर्न सकिन्छ. | बाइन्डर जेटिंग प्रिन्टरहरू प्रयोग गरेर मुद्रित कम्पोनेन्टहरू सुपर ग्लु प्रयोग गरेर बाँड्न सकिन्छ. |

| प्राइमिङ र पेन्टिङ | SLA कम्पोनेन्टहरू इच्छित फिनिश प्राप्त गर्न चित्रित गर्न सकिन्छ. | FDM कम्पोनेन्टहरू इच्छित फिनिश प्राप्त गर्न चित्रित गर्न सकिन्छ. | SLS कम्पोनेन्टहरू इच्छित फिनिश प्राप्त गर्न चित्रित गर्न सकिन्छ. | पूर्ण-रङ भागहरूको लागि कुनै पेन्टिङ आवश्यक छैन. |

वास्तविक-विश्व अनुप्रयोगहरू र केस स्टडीहरू

3डी प्रिन्टिङ भविष्यको अवधारणा मात्र होइन - यसले पहिल्यै तरङ्गहरू बनाइरहेको छ र वास्तुकलाको संसारमा महत्त्वपूर्ण मूल्य प्रदान गरिरहेको छ।. केही वास्तविक-विश्व अनुप्रयोगहरू अन्वेषण गरौं र अग्रणी फर्महरूले कसरी आफ्नो फाइदाको लागि यो प्रविधि प्रयोग गरिरहेका छन् हेर्नुहोस्:

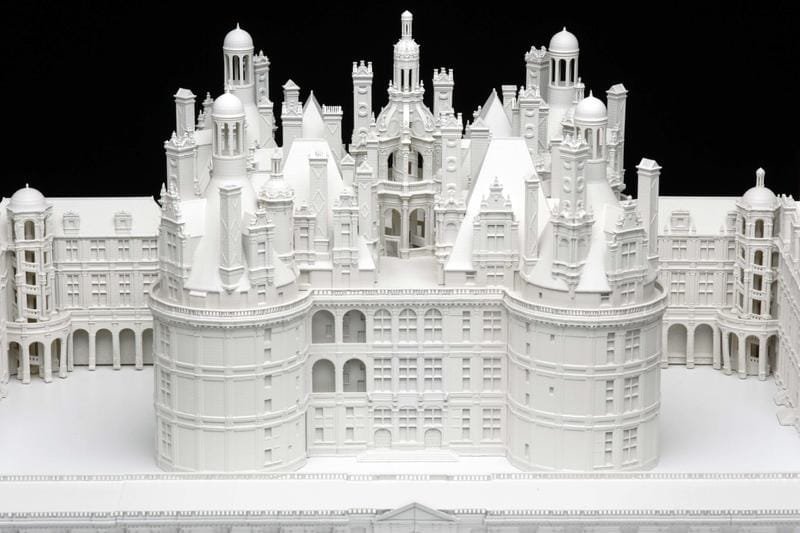

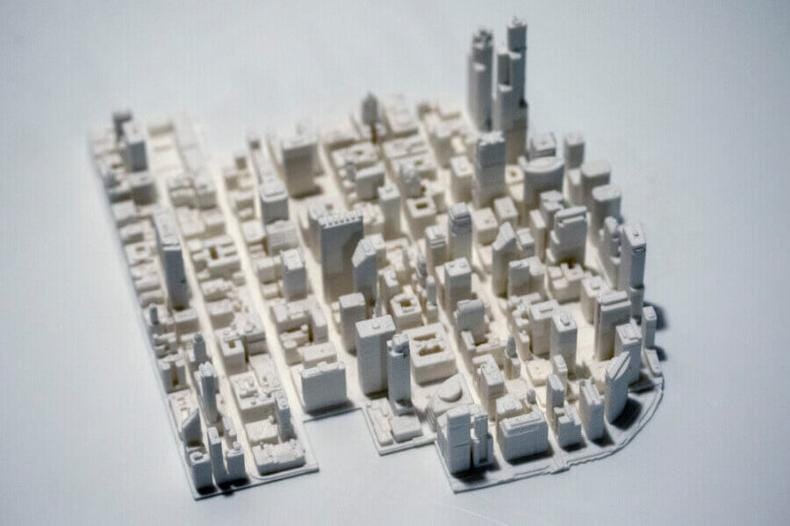

अवधारणा मोडेलहरू

डिजाइन को प्रारम्भिक चरण मा, वास्तुविद्हरूले अक्सर विभिन्न विचारहरू अन्वेषण गर्न र भवनको समग्र रूपको कल्पना गर्न अवधारणा मोडेलहरू सिर्जना गर्छन्।. 3डी प्रिन्टिङ यस उद्देश्यका लागि उपयुक्त छ, किनकि यसले द्रुत प्रोटोटाइप र द्रुत पुनरावृत्तिहरूको लागि अनुमति दिन्छ. आर्किटेक्टहरूले रातारात डिजाइनका धेरै भिन्नताहरू प्रिन्ट गर्न सक्छन् र बिहानको बैठकमा तिनीहरूलाई छेउ-छेउमा तुलना गर्न सक्छन्।, तिनीहरूलाई चाँडै सूचित निर्णय गर्न मद्दत.

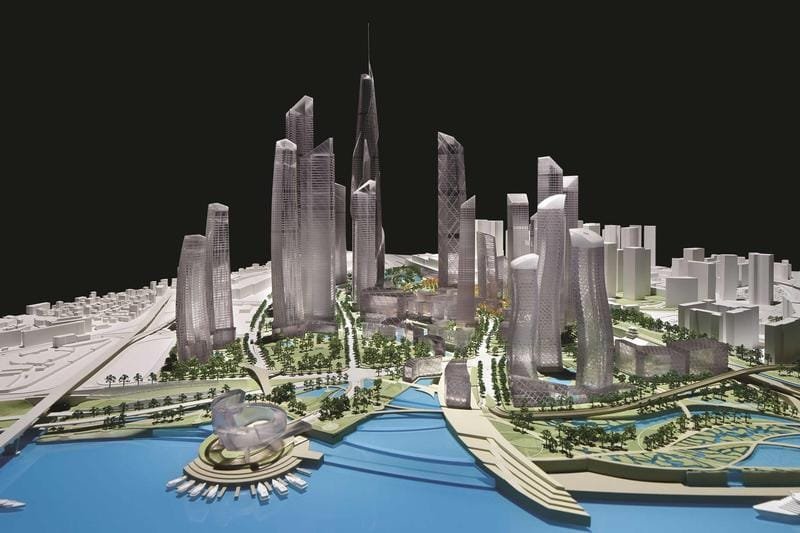

साइट योजना

भवनले आफ्नो वरपरको वातावरणसँग कसरी अन्तरक्रिया गर्छ भन्ने कुरा बुझ्नु महत्त्वपूर्ण छ. वास्तुविद्हरूले वरपरको क्षेत्रको CNC-मिल गरिएको टोपोग्राफिकल नक्साहरूसँग 3D मुद्रित भवनहरू संयोजन गरेर विस्तृत साइट मोडेलहरू सिर्जना गर्न सक्छन्।. यसले तिनीहरूलाई परिदृश्यसँग भवनको सम्बन्धको मूल्याङ्कन गर्न अनुमति दिन्छ, सूर्यको प्रकाश र छायाँको विश्लेषण गर्नुहोस्, र यसको सन्दर्भको लागि डिजाइनलाई अनुकूलन गर्न समायोजन गर्नुहोस्.

संरचनात्मक प्रोटोटाइपहरू

जटिल वा अपरंपरागत संरचनात्मक तत्वहरूको लागि, 3परीक्षण र विश्लेषणको लागि प्रोटोटाइपहरू सिर्जना गर्न D मुद्रण प्रयोग गर्न सकिन्छ. वास्तुकारहरूले जटिल संरचनाहरूको स्केल-डाउन संस्करणहरू प्रिन्ट गर्न सक्छन्, जस्तै cantilevered बीम वा अद्वितीय ज्यामितीय आकारहरू, र तिनीहरूको स्थिरता र भार वहन क्षमताको मूल्याङ्कन गर्नुहोस्. यसले सम्भावित संरचनात्मक चुनौतिहरूलाई निर्माण साइटमा महँगो समस्याहरू बन्नु अघि नै पहिचान गर्न मद्दत गर्छ.

अनुकूलित कम्पोनेन्टहरू

स्केल मोडेलहरू बाहिर, 3डी प्रिन्टिङ पनि वास्तविक भवन अवयवहरू सिर्जना गर्न प्रयोग गर्न सकिन्छ. जटिल अनुहारहरू सोच्नुहोस्, सजावटी प्यानलहरू, वा अनुकूलित फर्नीचर पनि. यसले अद्वितीय र व्यक्तिगत वास्तुकला तत्वहरू सिर्जना गर्न रोमाञ्चक सम्भावनाहरू खोल्छ जुन परम्परागत विधिहरू प्रयोग गरेर उत्पादन गर्न गाह्रो वा महँगो हुनेछ।. IAAC जटिल सजावटी प्यानलहरू बनाउन 3D प्रिन्टरहरू प्रयोग गरेको छ, मुखौटा तत्वहरू, र सम्पूर्ण पर्खालहरू पनि.

सहरी योजना र विकास

3D प्रिन्टेड मोडेलहरू शहरी योजनाकारहरू र विकासकर्ताहरूको लागि अमूल्य उपकरणहरू हुन्. तिनीहरू शहरी दृश्यहरूको व्यापक मोडेलहरू सिर्जना गर्न प्रयोग गर्न सकिन्छ, सरोकारवालाहरूलाई नयाँ विकासको प्रभाव कल्पना गर्न अनुमति दिँदै, ट्राफिक प्रवाह विश्लेषण, र भवन र सार्वजनिक स्थानहरू बीचको सम्बन्ध अध्ययन गर्नुहोस्. यी मोडेलहरू प्रायः सार्वजनिक परामर्श र लगानीकर्ता प्रस्तुतिहरूको केन्द्रबिन्दु हुन्.

केस स्टडीज

- पवित्र परिवार: बार्सिलोना मा यो प्रतिष्ठित बासिलिका, एन्टोनी गौडी द्वारा डिजाइन गरिएको, एक शताब्दीभन्दा बढी समयदेखि निर्माणाधीन छ. हालैका वर्षहरूमा, 3बाँकी खण्डहरूको जटिल मोडेलहरू सिर्जना गर्न D मुद्रण प्रयोग गरिएको छ, आर्किटेक्ट र इन्जिनियरहरूलाई गौडीको जटिल डिजाइनहरू बुझ्न र निर्माण प्रक्रियाको योजना बनाउन मद्दत गर्ने.

“गौडीको मूल परियोजनाको सतहहरू र आकारहरूको जटिलता दिएर, 2D मा काम गर्ने वास्तुकलाको दृष्टिकोणबाट कुनै अर्थ छैन।” – जोडी कोल, प्रमुख वास्तुकार

- हेनिङ लार्सन आर्किटेक्ट्स (HLA): यो कोपेनहेगन-आधारित फर्मले डिजाइन अन्वेषणको लागि थ्रीडी प्रिन्टिङलाई प्रमुख उपकरणको रूपमा अँगालेको छ. तिनीहरूले यसलाई तिनीहरूको परियोजनाहरूको विस्तृत मोडेलहरू सिर्जना गर्न प्रयोग गर्छन्, तिनीहरूलाई विभिन्न रूपहरू प्रयोग गर्न अनुमति दिँदै, सामग्री, र स्थानिक कन्फिगरेसनहरू.

“यस मेसिनले हामीलाई रङ तत्वहरू प्रिन्ट गर्न र प्रक्रियाको सुरुदेखि नै भवनहरूको 3D मोडेलहरू निर्माण गर्न अनुमति दिएर भौतिक संसार र डिजिटल संसारको बीचमा धेरै नजिकको सम्बन्ध सिर्जना गरेको छ।” – मोर्टेन स्टेफेन्सन, HLA इन्जिनियर

- Renzo पियानो भवन कार्यशाला (RPBW): तिनीहरूको अभिनव डिजाइनहरूको लागि परिचित, RPBW ले 3D प्रिन्टिङ प्रयोग गर्दछ जटिल जोडहरू र तिनीहरूको मोडेलहरूको लागि जटिल घटकहरू सिर्जना गर्न. उदाहरण को लागी, तिनीहरूले जेनोवामा सान जर्जियो ब्रिज मोडेलको स्तम्भहरूको लागि जटिल जोडहरू 3D प्रिन्ट गरे।.

वास्तुकला मा 3D मुद्रण को भविष्य

आर्किटेक्चरमा थ्रीडी प्रिन्टिङका अनुप्रयोगहरू आगामी वर्षहरूमा मात्र विस्तार हुँदैछन्. हामीले हाम्रो लेखमा यस विषयलाई गहिराइमा राख्छौं, मोडेल निर्माण को भविष्य: अन्तरक्रियात्मक टेक र एआर. हेर्नको लागि यहाँ केहि रोमाञ्चक घटनाक्रमहरू छन्:

पूर्ण-स्तरीय निर्माण

सम्पूर्ण भवनहरू साइटमा थ्रीडी प्रिन्ट गरिएको कल्पना गर्नुहोस्! यो विज्ञान कथा होइन - यो पहिले नै भइरहेको छ. कंक्रीट थ्रीडी प्रिन्टिङ र रोबोटिक एडिटिभ निर्माण निर्माण उद्योगमा क्रान्ति ल्याउन सक्ने उदीयमान प्रविधिहरू हुन्।, छिटो निर्माण समयको प्रतिज्ञा गर्दै, कम लागत, र कम अपशिष्ट. कम्पनीहरूले मन पराउँछन् एपिस कोर र COBOD यस क्षेत्रमा नेतृत्व गरिरहेका छन्.

एआई र जेनेरेटिभ डिजाइन

कृत्रिम बुद्धिमत्ता (AI) 3D प्रिन्टिङका लागि डिजाइनहरू अनुकूलन गर्न प्रयोग गर्न सकिन्छ, संरचनात्मक अखण्डता जस्ता कारकहरूलाई ध्यानमा राख्दै, सामग्री प्रयोग, र खर्च. जेनेरेटिभ डिजाइन एल्गोरिदमले मापदण्डहरूको विशिष्ट सेटमा आधारित हजारौं पूर्ण रूपमा नयाँ डिजाइन विकल्पहरू सिर्जना गर्न सक्छ।, मानव अन्तर्ज्ञान भन्दा पर वास्तु रचनात्मकता को सीमाहरु धकेल्दै.

दिगो सामग्री

वातावरणीय चिन्ता बढ्दै जाँदा, पर्यावरण-मैत्री थ्रीडी मुद्रण सामग्रीको विकास बढ्दो महत्त्वपूर्ण हुँदै गइरहेको छ. अनुसन्धानकर्ताहरूले रिसाइकल प्लास्टिकको प्रयोगको खोजी गरिरहेका छन्, बाँस र माइसेलियम जस्ता जैव-आधारित सामग्री (मशरूम को जरा संरचना), र पनि अभिनव सामग्री जस्तै बालुवा थ्रीडी प्रिन्टिङमा.

बढेको पहुँच

थ्रीडी प्रिन्टिङ टेक्नोलोजी विकसित र परिपक्व हुन जारी छ, वास्तुकार र डिजाइनरहरूको फराकिलो दायराको लागि यो अझ किफायती र पहुँचयोग्य हुँदै गइरहेको छ. टेक्नोलोजीको यो प्रजातान्त्रिककरणले सम्भवतः अझ बढी नवीन अनुप्रयोगहरू र दैनिक वास्तुकला कार्यप्रवाहमा 3D प्रिन्टिङको ठूलो एकीकरणको नेतृत्व गर्नेछ।.

चुनौतिहरु र विचारहरु

जबकि थ्रीडी प्रिन्टिङले अविश्वसनीय सम्भावना प्रदान गर्दछ, चुनौतीहरू र सीमितताहरूलाई स्वीकार गर्न महत्त्वपूर्ण छ जुन अझै अवस्थित छ. यी सफलतापूर्वक नेभिगेट गर्ने प्रायः अनुभवी फर्मसँग साझेदारी गर्ने कुरा हो, एक प्रक्रिया जसमा हामी रूपरेखा गर्छौं 10 तपाईंको मोडेल निर्मातालाई सोध्नको लागि महत्वपूर्ण प्रश्नहरू.

प्राविधिक बाधाहरू

- प्रिन्ट साइज सीमाहरू: धेरैजसो डेस्कटप थ्रीडी प्रिन्टरहरूसँग तुलनात्मक रूपमा सानो निर्माण भोल्युमहरू छन्, जुन ठूला वास्तुकला मोडेलहरू मुद्रण गर्दा बाधा हुन सक्छ. जबकि ठूला औद्योगिक प्रिन्टरहरू अवस्थित छन्, तिनीहरू धेरै उच्च मूल्य ट्यागको साथ आउँछन्.

- रिजोल्युसन र सतह गुणस्तर: जबकि थ्रीडी प्रिन्टिङ टेक्नोलोजीले लामो यात्रा गरिसकेको छ, तह रेखाहरू र थोरै त्रुटिहरू अझै पनि देख्न सकिन्छ, विशेष गरी FDM प्रविधिसँग मुद्रित मोडेलहरूमा. पूर्ण रूपमा चिकनी फिनिश प्राप्त गर्न महत्त्वपूर्ण अतिरिक्त पोस्ट-प्रोसेसिङ आवश्यक पर्दछ.

- सामग्री प्रदर्शन: सबै थ्रीडी मुद्रण सामग्रीहरू पूर्ण रूपमा परम्परागत निर्माण सामग्रीको गुणहरू प्रतिकृति गर्न सक्दैन. सावधानीपूर्वक बललाई ध्यान दिएर महत्त्वपूर्ण छ, टिकाउ, र छनोट गरिएको सामग्रीको अन्य विशेषताहरू यसले परियोजनाका आवश्यकताहरू पूरा गरेको सुनिश्चित गर्न.

आर्थिक विचारहरू

- प्रारम्भिक लगानी: विस्तृत वास्तुकला मोडेलहरू उत्पादन गर्न सक्षम उच्च गुणस्तर 3D प्रिन्टरहरू महत्त्वपूर्ण लगानी हुन सक्छ।, विशेष गरी साना फर्महरू वा व्यक्तिगत वास्तुकारहरूको लागि.

- सामग्री लागत: विशेष 3D मुद्रण सामग्री, जस्तै उच्च-रिजोल्युसन रेजिन वा इन्जिनियरिङ-ग्रेड फिलामेन्टहरू, परम्परागत मोडलिङ सामग्री भन्दा महँगो हुन सक्छ.

दिगोपन र वातावरणीय प्रभाव

- ऊर्जा खपत: 3D मुद्रण ऊर्जा-गहन हुन सक्छ, विशेष गरी ठूला वा जटिल मोडेलहरूको लागि जुन लामो प्रिन्ट समय चाहिन्छ.

- भौतिक फोहोर: जबकि थ्रीडी प्रिन्टिङले सामान्यतया परम्परागत घटाउने विधिहरू भन्दा कम फोहोर उत्पादन गर्छ, असफल प्रिन्टहरू र समर्थन संरचनाहरूले अझै पनि फोहोरमा योगदान दिन सक्छ. जिम्मेवारीपूर्वक सामग्रीहरू प्रयोग गर्न र सम्भव भएसम्म रिसाइकल विकल्पहरू अन्वेषण गर्न महत्त्वपूर्ण छ.

वास्तुकलामा थ्रीडी प्रिन्टिङका सीमितताहरू के हुन्??

यहाँ चुनौतीहरूको द्रुत सारांश हो:

| चुनौती | वर्णन |

|---|---|

| प्राविधिक बाधाहरू | प्रिन्ट साइजमा सीमितताहरू, संकल्प, र भौतिक गुणहरूले अन्तिम परिणामलाई असर गर्न सक्छ. |

| आर्थिक विचारहरू | व्यावसायिक-ग्रेड उपकरणहरूमा उच्च प्रारम्भिक लगानी र सम्भावित रूपमा उच्च सामग्री लागत. |

| दिगोपन | समर्थन र असफल प्रिन्टहरूबाट ऊर्जा खपत र प्लास्टिकको फोहोरको बारेमा चिन्ता. |

| सीप र प्रशिक्षण | 3D मोडलिङमा विशेष ज्ञान चाहिन्छ, काट्ने सफ्टवेयर, र प्रिन्टर सञ्चालन उच्च गुणस्तर परिणाम प्राप्त गर्न. |

सीप र प्रशिक्षण

- विशेषज्ञता आवश्यक छ: वास्तुकला मोडलिङको लागि थ्रीडी प्रिन्टिङ प्रभावकारी रूपमा प्रयोग गर्न विशेष ज्ञान र सीपहरू चाहिन्छ. आर्किटेक्ट र डिजाइनरहरू 3D मोडलिङ सफ्टवेयरमा निपुण हुन आवश्यक छ, विभिन्न थ्रीडी प्रिन्टिङ प्रविधिहरूको जटिलताहरू बुझ्नुहोस्, र स्लाइसिङ सफ्टवेयर र प्रिन्ट सेटिङहरूको सूक्ष्मताहरू मास्टर गर्नुहोस्.

- सफ्टवेयर र हार्डवेयर प्रवीणता: आधारभूत सञ्चालन बाहिर, प्रिन्टर क्यालिब्रेसनको गहिरो बुझाइ, समस्या निवारण, र निरन्तर र उच्च गुणस्तर परिणामहरूको लागि मर्मत आवश्यक छ. यसले प्रायः महत्त्वपूर्ण सिकाइ वक्र र नवीनतम प्रगतिहरूसँग अद्यावधिक रहन जारी प्रशिक्षण समावेश गर्दछ.

सफलताको लागि सुझावहरू

तपाईंको वास्तुकला मोडेलहरूको लागि 3D प्रिन्टिङको अधिकतम बनाउन, यी सुझावहरू दिमागमा राख्नुहोस्:

- तपाईंको प्रिन्टर नियमित रूपमा क्यालिब्रेट गर्नुहोस्: सही क्यालिब्रेसन सही र लगातार प्रिन्टहरूको आधार हो.

- उच्च गुणस्तरीय सामग्री प्रयोग गर्नुहोस्: तपाईंको फिलामेन्ट वा रालको गुणस्तरले बललाई महत्त्वपूर्ण रूपमा असर गर्न सक्छ, बेहोरा, र अन्तिम परिणाम को समाप्त.

- प्रिन्ट सेटिङहरू अनुकूलन गर्नुहोस्: तपाईंको विशिष्ट मोडेल र सामग्रीको लागि उत्तम संयोजन फेला पार्न विभिन्न सेटिङहरूसँग प्रयोग गर्नुहोस्.

- मास्टर पोस्ट-प्रोसेसिङ प्रविधिहरू: कसरी प्रभावकारी रूपमा समर्थन हटाउने जान्नुहोस्, बालुवा सतहहरू, र एक पेशेवर फिनिश प्राप्त गर्न आफ्नो मोडेल रंग.

- प्रयोग र पुनरावृत्ति: नयाँ चीजहरू प्रयास गर्न र आफ्नो गल्तीहरूबाट सिक्न नडराउनुहोस्. थ्रीडी प्रिन्टिङको लचिलोपन यसको सबैभन्दा ठूलो शक्ति हो.

निष्कर्ष

3डी मुद्रण एक शक्तिशाली छ, परिवर्तनकारी उपकरण जसले मौलिक रूपमा वास्तु मोडलिङको क्षेत्रमा परिवर्तन गर्दैछ. यसले वास्तुकारहरूलाई विस्तृत सिर्जना गर्न अधिकार दिन्छ, सही, र अभूतपूर्व गति र लचिलोपनको साथ लागत-प्रभावी मोडेलहरू. यस प्रविधिलाई अंगालेर, आर्किटेक्टहरूले आफ्नो डिजाइन प्रक्रिया बढाउन सक्छन्, ग्राहकहरु संग संचार सुधार, र रचनात्मकता को सीमाहरु धकेल्नुहोस्. जबकि चुनौतीहरू बाँकी छन्, थ्रीडी प्रिन्टिङ टेक्नोलोजीमा निरन्तर प्रगति, सामग्री, र सफ्टवेयरले वास्तुकलामा यसको प्रयोगको लागि अझ रोमाञ्चक भविष्यको वाचा गर्दछ. प्रविधि थप पहुँचयोग्य र प्रयोगकर्ता-अनुकूल बन्दै गएको छ, हामी भोलिका भवनहरू र शहरहरूको डिजाइन र निर्माणमा थ्रीडी प्रिन्टिङको थप अभिनव प्रयोगहरू हेर्ने आशा गर्न सक्छौं।.

तपाईंको वास्तुकला मोडेलहरूलाई अर्को स्तरमा लैजान तयार छ? थ्रीडी प्रिन्टिङको संसारको अन्वेषण गर्नुहोस् र यसले तपाईंको डिजाइन प्रक्रियालाई कसरी क्रान्तिकारी बनाउन सक्छ भनेर पत्ता लगाउनुहोस्. चाहे तपाईं थ्रीडी प्रिन्टरमा लगानी गर्ने वा थ्रीडी प्रिन्टिङ सेवा प्रदायकसँग साझेदारी गर्ने विचार गर्दै हुनुहुन्छ। FacFox, सम्भावनाहरू अनन्त छन्. प्रयोग सुरु गर्नुहोस्, आफ्नो रचनात्मकता खोल्नुहोस्, र आश्चर्यजनक 3D प्रिन्ट गरिएको विवरणमा तपाईंको वास्तुकलाको दर्शनहरू जीवित भएको हेर्नुहोस्! तपाईं जस्तै अनलाइन समुदायहरू पनि जाँच गर्न सक्नुहुन्छ r/3Dprinting अन्य उत्साहीहरूसँग जडान गर्न subreddit, सुझाव साझा गर्नुहोस्, र उनीहरूको अनुभवबाट सिक्नुहोस्.