Оглавление

A New Paradigm in High-Value Architectural Fabrication

Представьте себе это: A leading architectural firm in New York is preparing for a design competition. Одновременно, a major property developer in Dubai is planning the launch of a flagship luxury tower. When it comes time to commission their most critical physical marketing asset—the architectural model—both firms make the same strategic choice. They partner with a specialized workshop not in their home city, but in a bustling manufacturing hub in China’s Pearl River Delta.

В течение десятилетий, the phrase “Made in China” was often associated with low-cost, mass-produced consumer goods. It’s a perception rooted in history, but one that is now profoundly outdated when it comes to high-value, bespoke fabrication. Сегодня, for complex products like world-class architectural models, sourcing from China is no longer a simple cost-cutting tactic. It has evolved into a powerful strategic decision to access an unparalleled ecosystem of scale, deep skill, and advanced technology.

This in-depth guide will provide a transparent analysis of the key strategic advantages driving this global shift. We will unpack the compelling business case, de-risk the common concerns around logistics and communication, and provide a clear framework for how international firms can leverage “Преимущество Китая” to their benefit. This decision is part of a larger strategy for creating world-class presentations. To understand the full context, we recommend starting with our foundational pillar page: Конечное руководство по высококачественным архитектурным моделям.

The First Pillar: Unmatched Scale, Скорость, and Capacity

The most visible advantage of China’s manufacturing sector is its sheer scale. But what does this mean in the context of a highly specialized, one-of-a-kind product like an architectural model? It’s not about mass production. It translates to three key benefits for a global client: immense capacity, incredible speed, and the unique ability to tackle projects of unprecedented complexity.

The Power of the “Workshop City”: Industrial Clusters and Supply Chain Integration

Top model-making firms in China are not just isolated factories; they are hubs within vast, hyper-specialized industrial clusters. Think of it as an entire city dedicated to making things. Within a few square miles, a model maker has immediate access to a deeply integrated supply chain: hundreds of suppliers of every grade of acrylic, древесина, и металл; specialized toolmakers; and vendors for every conceivable electronic component, from micro-LEDs to custom-programmed circuit boards.

The Client Benefit: This integrated ecosystem dramatically reduces lead times for materials and allows for incredible agility. If a project requires a unique, non-standard component, it can be sourced or custom-fabricated locally in days, not weeks. This eliminates supply chain bottlenecks that can plague smaller, more isolated workshops in other parts of the world.

Unparalleled Production Speed: Meeting Mission-Critical Deadlines

This is where scale directly translates to speed. A large facility with over 250 skilled artisans has the human resources to operate in multiple shifts, 24/7 if required, to meet aggressive, immovable deadlines for major international property expos like MIPIM in Cannes or Cityscape in Dubai. This is not about rushing the work; it’s about parallelizing it.

“In a small workshop, a model is built sequentially. In a large, specialized facility, it is built simultaneously. That is the difference between weeks and months.”

А “parallel workflow” means that while one dedicated team is CNC milling the topographical base, another is laser-cutting the facade components, a third is assembling the building cores, and a fourth is hand-crafting the landscape elements. All these processes happen at the same time, converging for final assembly. This operational model is a game-changer for projects on a tight schedule.

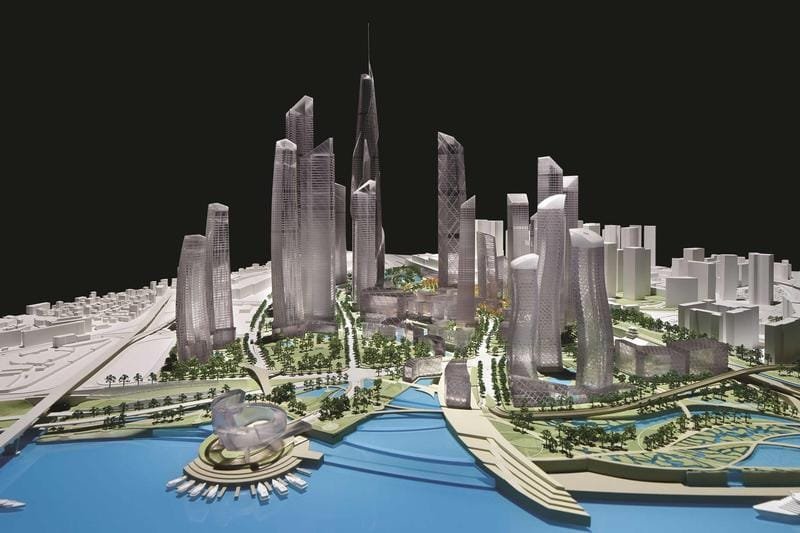

Handling the Unprecedented: The Capacity for Mega-Projects

What happens when a project’s vision exceeds the physical or logistical capabilities of local model makers? This is a common challenge for firms designing mega-projects. A top-tier Chinese firm has the sheer physical space and manpower to take on projects that are often too large, too numerous, or too intricate for workshops elsewhere.

Это включает в себя:

- Enormous City-Scale Models: Crafting full-city модели генерального плана that can fill an entire room.

- High-Volume Developments: Creating hundreds of individual, highly detailed building models for a massive multi-phase residential community.

- Logistically Complex Projects: Building and coordinating the delivery of multiple large models to different continents for a simultaneous global launch.

The Client Benefit: Ambitious architects and developers are not constrained by the limitations of their local market. They can dream big, knowing that there are partners with the capacity to execute their vision at any scale.

The Second Pillar: Deep Skill, Craftsmanship, and Technology

The second pillar of the China Advantage directly confronts and dismantles the outdated stereotype of low-quality production. Modern Chinese model making is defined by a powerful and unique fusion: a deep, cultural legacy of fine craftsmanship augmented by massive, ongoing investment in state-of-the-art digital fabrication technology.

A Deep Legacy of Artisanship: The Human Element

Long before the era of digital manufacturing, China had a rich history of intricate carving, fine lacquerwork, and detailed artisanship. This cultural legacy provides a deep pool of highly skilled craftspeople who have spent their entire careers perfecting tactile skills. These are not simply assembly line workers; they are master artisans who handle the final, crucial 10% of a model that technology cannot replicate—the subtle weathering on a brick facade, the delicate airbrushing on a landscape, the flawless assembly of a thousand tiny pieces. This synergy is a topic we explore in our guide on Модерн Крафт против. Традиционная ручная работа.

Massive Investment in Digital Fabrication Technology

The top model-making firms in China are engaged in a technological arms race, continuously investing in the latest and best equipment at an industrial scale.

Fleets of 3D Printers

A leading workshop won’t have just one or two 3D printers. They will have entire climate-controlled rooms filled with a fleet of large-format Stereolithography (СЛА) and Selective Laser Sintering (SLS) machines running 24/7. This allows for the rapid production of incredibly complex, one-piece facades, intricate structural elements, and detailed interior furnishings that would be physically impossible to create by hand. The impact of this technology is profound, as we detail in Революция 3D-печати в архитектуре.

Advanced CNC and Laser Cutting

Precision is paramount. These facilities utilize 5-axis CNC mills to carve complex, multi-layered topographical bases with perfect accuracy. Their workshops are equipped with multiple high-powered laser cutters that can slice through thick acrylic and wood with a clean, polished edge, eliminating the need for time-consuming manual finishing.

The Client Benefit: This massive technological infrastructure guarantees a level of precision and complexity that is perfectly faithful to the architect’s most ambitious CAD files. What you design digitally is what you get physically.

Искусство финиша: Where World-Class Quality is Revealed

The final finish is what separates a good model from a breathtaking one. This is where the fusion of technology and artisanship truly shines.

Автомобильная покраска

A professional firm uses dedicated, dust-free, positive-pressure spray booths, identical to those used for luxury cars. Artisans use high-quality automotive paints and sophisticated airbrushing techniques to achieve flawless, прочный, and perfectly color-matched finishes. They can replicate the subtle sheen of brushed aluminum, the matte texture of concrete, or the glossy finish of a skyscraper’s curtain wall with stunning realism. The choice of the right finish is critical, a subject we cover in our Руководство по материалам и отделке моделей.

Гиперреалистичный ландшафтный дизайн

This is a key differentiator of a top-tier firm. It involves an almost obsessive attention to detail. Instead of generic, identical green sponges for trees, master artisans will create hundreds of unique, hand-made trees of varying species and heights. Water features will have realistic depth and texture. Ground cover will be multi-layered and subtly colored. This transforms the model’s base from a simple platform into a convincing, living environment. We explore this art form in Секреты реалистичного модельного ландшафтного дизайна.

The Third Pillar: The Unmatched Value Proposition

It is an undeniable fact that sourcing models from China is often more cost-effective. Однако, it is a strategic error to frame this simply as “дешевле.” The true advantage lies in the powerful value proposition: the ability to achieve a level of quality, деталь, шкала, and technological sophistication that would be prohibitively expensive—or in some cases, simply impossible—to procure in other markets.

The Components of Cost Efficiency

This value is not derived from cutting corners. It’s the result of a highly optimized manufacturing ecosystem.

| Efficiency Driver | Как это работает | Benefit to Client |

|---|---|---|

| Economies of Scale | Large-scale operations purchase raw materials like acrylic and wood in massive bulk quantities, securing significant discounts. | Lower raw material costs are passed on to the client. |

| Supply Chain Proximity | Being located within a manufacturing hub eliminates costly and time-consuming shipping for all necessary materials and electronic components. | Faster project start times and no budget inflation from inbound freight costs. |

| Labor Specialization | A large team allows for extreme specialization. A painter only paints; an electronics expert only does wiring. This increases both speed and quality. | Higher quality in less time compared to a generalist in a small shop who must perform multiple tasks. |

The Value Equation: What Your Budget Actually Buys

This is the bottom line for a developer or architect. For the same budget that might get you a “good” quality model with moderate detail and basic lighting from a local Western shop, you can commission a “мирового класса” quality model from a top-tier Chinese firm that includes a higher level of detail, fully furnished interiors, a more realistic landscape, and a sophisticated, динамика lighting system.

The Client Benefit: You are not sacrificing quality for price. You are leveraging an efficient ecosystem to get more quality, more detail, and more impact for your investment. To fully appreciate this, it is essential to understand the factors that drive cost, which we explain in our guide, Распаковывать 5 Ключевые факторы ценообразования архитектурной модели.

De-Risking the Decision: Overcoming the Core Concerns

For any prudent international client, the immense advantages are weighed against two primary concerns: the risk of shipping a fragile, high-value item across the globe, and the challenges of managing a complex creative project across time zones and cultures. A professional firm has engineered robust solutions for both.

Overcoming the Tyranny of Distance: The Science of Global Logistics

The biggest fear is valid: “Will my model survive a 10,000 КМ путешествие?” The answer from an expert firm is a confident “да,” because they treat logistics as a science, not an afterthought.

- Designing for Transit: The process starts in the design phase. Large models are engineered to be sectional, breaking down into smaller, more robust modules that are safer to ship and easier to handle on-site.

- А “Пуленепробиваемый” Ящик: The standard is a custom-built, heat-treated plywood crate. Внутри, the model is not just surrounded by foam; it’s secured to a “плавучая база” that is then suspended on all sides by shock-absorbing foam. This isolates it from vibration and impact.

- Navigating Customs: An experienced firm has a dedicated logistics team that handles all paperwork, ensuring correct commercial invoices and Harmonized System (HS) codes are used to prevent any delays at the border.

We consider logistics to be a core competency. You can learn every detail of this process in our definitive Руководство по безопасной международной модели доставки.

Bridging the Communication Gap: The Modern International Workflow

The second major fear is communication: “How will I manage this process from so far away?” Modern tools and a client-centric process have made this seamless.

- Your Dedicated, Bilingual Project Manager: This is the linchpin. You are assigned a single PM who is fluent in English and an expert in architecture and model making. They are your partner and advocate from start to finish.

- A System of Radical Transparency: A professional workflow includes a formal project kick-off video call, a shared digital workspace for all files, and—most importantly—scheduled weekly progress reports with high-resolution photos and detailed notes. You will see your model come to life every step of the way.

- Technology as the Bridge: Tools like Zoom, WhatsApp, and high-resolution cameras make real-time collaboration effortless. You can have a virtual tour of your model in the workshop from the comfort of your office.

This seamless process is by design. You can read more about it in our Руководство по управлению зарубежными проектами.

Finding Your Partner: A Vetting Checklist

Not all firms in China are created equal. To find a true world-class partner, you must conduct thorough due diligence. Use this checklist to vet potential suppliers.

| Area of Concern | What to Demand | Красный Флаг |

|---|---|---|

| Емкость & Шкала | Specific numbers on team size and facility square footage. | Vague answers like “a large team.” |

| Технология | A specific list of their in-house machinery (НАПРИМЕР., number and type of 3D printers). | “We work with trusted partners” (meaning they outsource). |

| Logistics Expertise | A detailed explanation of their crating, документация, and insurance process. | A simple promise to “pack it carefully.” |

| Коммуникация | Assignment of a dedicated, bilingual Project Manager. | No single point of contact assigned. |

| Portfolio Relevance | Examples of projects that are directly comparable to yours in scale and type. | Showing beautiful but irrelevant work. |

This checklist is a summary of a deeper process. For the full list of questions and what to look for in the answers, you must read our comprehensive guide: 10 Критические вопросы, которые нужно задать, прежде чем нанимать модельного производителя.

Заключение: Your New Global Competitive Edge

The decision to source an architectural model from a top-tier firm in China is no longer about finding the lowest bidder. It’s about making a strategic choice to access a world-leading manufacturing ecosystem. The China Advantage is a powerful, proven combination of Шкала, Skill, and Value. This trifecta allows ambitious firms to produce models of a higher quality, большая сложность, and more profound impact than their budget would typically allow in their local market.

In a globalized world, leveraging the planet’s most advanced and efficient manufacturing hub is not an outsourcing risk; it is a smart business decision that provides a tangible competitive edge. The question is no longer if you should consider it, but how soon you can leverage The China Advantage to bring your own visionary projects to life.

Ready to Leverage The China Advantage for Your Next Landmark Project?

Our international team is ready to demonstrate the value, качество, and seamless process we bring to leading firms around the world. Свяжитесь с нами бесплатно, no-obligation consultation to discuss your next project.